The Diary of the Building of a Driving Trolley |

|

|

|

|

Driving Trolley build Truck 1 Truck 2 Truck 3 Truck 4 Truck 5 Truck 6 Truck 7 Truck 8 Truck 9 Truck 10 Truck 11 Truck 12 Truck 13 Truck 14/15 Truck 16 Truck 17 Truck 18 Truck 19 Truck 20 Truck 20/21 Truck 22 Truck 23 Truck 24/25 Truck 26 / 27 / 28 / 29 Truck 30 / 31 Truck 32 Light flasher

|

|

Construction Day 9

|

|

Only an evening of engineering to day !!!

|

|

|

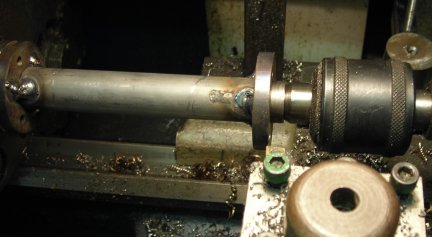

Originally I thought that I would

need the support that I made but after using is for the first cut I decided

to see if the alignment was good in the tube with the revolving centre alone

and it was so all the other cuts were made using only the revolving

centre.

Max depth of cut was 0.5mm All the wheel supports came out to 119mm to -118.9mm and i am happy with that tolerance.

|

|

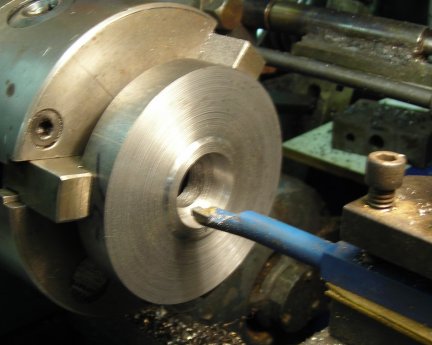

Here the lathe is set up to bore the recess for the wheel bearing it is 8mm deep and a nice fit to the outside of the bearing housing. |

|

Two wheel blanks completed the next

stage is to fit to an arbor and turn the treads and flange accurately.

The process for changing the wheel blanks into wheel so far carried out is as follows:-

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

If you have any comments / questions about the project then please email me ...

|

|