The Diary of the Building of a Driving Trolley |

|

|

|

|

Driving Trolley build Truck 1 Truck 2 Truck 3 Truck 4 Truck 5 Truck 6 Truck 7 Truck 8 Truck 9 Truck 10 Truck 11 Truck 12 Truck 13 Truck 14/15 Truck 16 Truck 17 Truck 18 Truck 19 Truck 20 Truck 20/21 Truck 22 Truck 23 Truck 24/25 Truck 26 / 27 / 28 / 29 Truck 30 / 31 Truck 32 Light flasher

|

|

Construction Day 18

|

|

Afternoon start to day

|

|

|

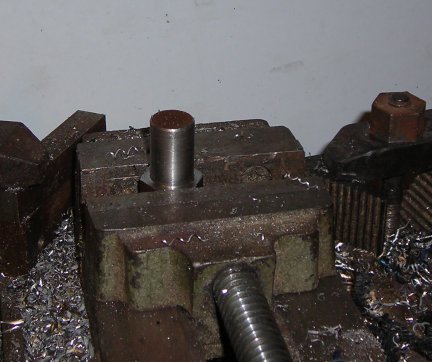

This may not look very important but it forms the basis of the accurate drill in the wheels ready for tapping 2BA threads. |

|

By placing a wheel blank on the bolts with the spacer beneath it stayed in one location but can be turned so that the three holes may easily be drilled. |

|

The guide made to drill the inner fixing parts of the axles is again used to drill the holes for the 2BA tapping thereby reducing error to a minimum. |

|

Once the first hole had been drill to a depth of 10mm the wheel blank was turned and a peg inserted that was a neat fit to the tapping holes and the guide holes. |

| To ensure that the tap stated straight

a guide was made up to be a good fit to the tap and this was held down tightly

whilst the first few turned of the "second" tap were used.

After this the stub end tap was used but it was found that the initial tapping was quite deep enough !! |

|

|

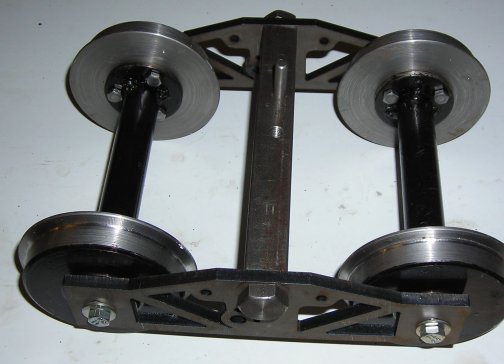

The centre part of the axel had the holes eased from 4.7mm which was a dead tight fit to the bolts to 5.1mm and this gave just the amount of freedom to ensure that the bolts tightened down square into the wheels!! |

|

Here are all the parts that go together

to make the bogie.

|

|

The completed first bogie. Now it needs to be taken apart and painted !!!! The wheels and axel centre will be marked to show the location of bolt position "1" and then the others will align. The bogie swivels as required BUT the fixing to stop the rotation of the axel need to be reconsidered as it is not a practical solution. I believe I will need to mill out a slot from one end of the axel for a depth of say 2mm the width of the slot in the frame then file up pieces to fit. The existing idea of the screwed in 4BA bolt section just down not work !!!! Later in the evening I was able to assemble all the other wheels to their centres and paint the inside of all wheels so that they are ready for final assembly. It is now looking very promising that I shall have a truck to put on the track on Wednesday to be able to do the measurements. |

|

|

|

If you have any comments / questions about the project then please email me ...

|

|