The Diary of the Building of a Driving Trolley |

|

|

|

|

Driving Trolley build Truck 1 Truck 2 Truck 3 Truck 4 Truck 5 Truck 6 Truck 7 Truck 8 Truck 9 Truck 10 Truck 11 Truck 12 Truck 13 Truck 14/15 Truck 16 Truck 17 Truck 18 Truck 19 Truck 20 Truck 20/21 Truck 22 Truck 23 Truck 24/25 Truck 26 / 27 / 28 / 29 Truck 30 / 31 Truck 32 Light flasher

|

|

Construction Days 24 & 25

|

|

Early morning start

|

|

|

The truck on the rails again at mote park. The foot rest pattern worked exactly as planned and now the real ones can be made. |

|

|

| Two further difference views of the truck. The difficult parts to assemble now are the braking system and I still have to learn how to caste aluminium - all that is in hand with another club member. | |

|

|

| Above shows the fire bricks

that have been obtain for the project. The left hand picture show the first

idea and I was to cut a hole in one of the bricks --- then I thought why

not just slide a brick out.

I have still to decide how to open the hot furnace ... 600c and be able to close it again !! The furnace will be fired on Propane gas from a torch which I used to boiler making and Raku Pottery firing. |

|

|

|

|

Construction Day 24 |

|

| The morning was not spent

idly in bed but at my ceramics class where discussion took place with the

tutor as to how to make crucibles and let's just say that that is work in

progress but the first crucibles should be ready in about two weeks time

!!

Work on the furnace took place in the afternoon. |

|

|

I had some spare Dexion - well it had been in the workshop for 10 years unused so thought cut it up and go for it. |

|

Decided that the furnace needed a

lift off top so that the crucible would be clear of all obstructions so a

cradle to carry the top section was made.

I have no Dexion left so the base section which does not need to be moved and should not get hot on the bottom will rest initially on a piece of Aluminium !!!! If that melts then the furnace bricks are not doing their job !!!! The hole in the lower layer is for the propane torch to fire its heat in. Photos will be taken asap of the test firing but at present the rain persists !!! |

|

Another view of the furnace. |

Construction Day 25 |

|

Today was a day of sorting out the furnace for the aluminium casting and progress has been made in that I not have a cylinder head that need to be cut up into small pieces and the steel items removed ready to melt down for the casting process. |

|

|

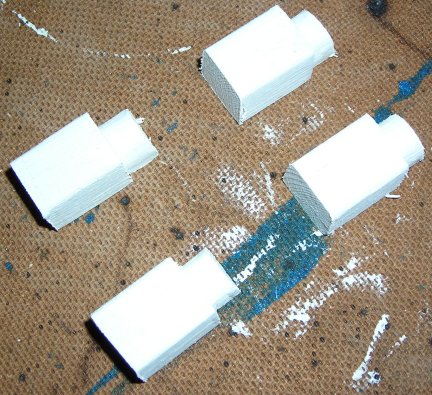

This is the timber pattern painted in white emulsion paint to make the ring from which the brake blocks will be made. |

|

Here are some patterns for lamps. The patterns have been made quickly so that there is something to start the casting and new patterns can be made when it is known how well these turn out - or otherwise !!!! |

|

The first parts of the braking system

has been made - the spacer which hold one of four brake blocks. It is the

"rusty" part you are looking for the other part was lazer cut. Eventually

a lock nut will be put on the exposed threaded part, and similarly on the

out side and probably tread lock used so that it cannot - should not come

loose.

So three more of these to make. The holes for the braking system had as expected to be drill out to size and the lazer cut was on purpose made a fraction under size. |

|

|

|

If you have any comments / questions about the project then please email me ...

|

|