The Diary of the Building of a Driving Trolley |

|

|

|

|

Driving Trolley build Truck 1 Truck 2 Truck 3 Truck 4 Truck 5 Truck 6 Truck 7 Truck 8 Truck 9 Truck 10 Truck 11 Truck 12 Truck 13 Truck 14/15 Truck 16 Truck 17 Truck 18 Truck 19 Truck 20 Truck 20/21 Truck 22 Truck 23 Truck 24/25 Truck 26 / 27 / 28 / 29 Truck 30 / 31 Truck 32 Light flasher

|

|

Construction Day 14 (Delivery Day / 15

(Workshop day after run of Ruston)

|

|

14th day a take delivery day - 15th Day

a workshop day.

|

|

| So what did Father Christmas

bring me ?

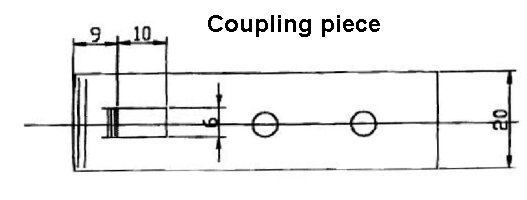

Well Martin of the Maidstone Model Engineering Society had arranged for me to have lazer cut many of the difficult part to make. Boxing Day 2006 was the day to collect and pay for them. I was not disappointed with the large collection of piece cut at a reasonable price and I also met up with the originators of the truck who pointed out some additions needed to the drawings. One part not included in the lazer cut is the coupling piece ....

|

|

|

It is hoped that the truck build will continue very soon!!! When completed the truck will be a great pleasure to use as it mean no longer would I have to use the club's trucks. This is the work bench with the steel ready for the next stage ...welding !!! |

|

So that was the first part to be made with design altered to take account of us with Electric loco Ruston. To ensure that the "bolt" and coupling are kept together there is a light cord attached!!! |

|

|

| Ok so we got the "Ruston

Loco" before Christmas but your have to play with your new toy so here we

are the day after Boxing day making the first run of a RUSTON loco by Maxitrak.

She went very well and now I will be making a voltage checker so that the

battery is run too low in and effort to ensure a good few seasons with the

loco.

Of course Paul had a run, well what would have been the point of him coming over to the track and not sharing in the fun ...and taking the photo of me!!! |

|

|

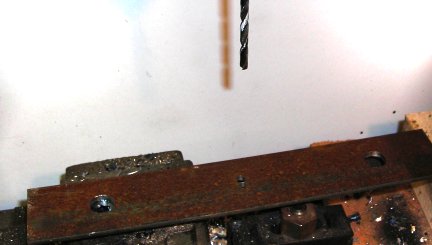

Drilling the buffer brackets for the buffers and for the rectangular slot for the hook. |

|

Completed buffer with hook that was lazer cut in place. I am very glad that the hook was lazer cut. |

|

Some of the lazer cut pieces that have saved a great deal of time and will improve the general look of the truck. |

|

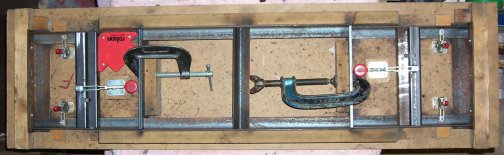

The person who designed the truck

has kindly loaned me the welding jig used for may other trucks.

Here it is empty of parts - you can quite clearly see the welding scaring!!! |

|

Here is the welding jig with the parts located and subject to final checking that all necessary holes have been drill ready for welding up. |

|

|

|

If you have any comments / questions about the project then please email me ...

|

|