The Diary of the Building of a Driving Trolley |

|

|

|

|

Driving Trolley build Truck 1 Truck 2 Truck 3 Truck 4 Truck 5 Truck 6 Truck 7 Truck 8 Truck 9 Truck 10 Truck 11 Truck 12 Truck 13 Truck 14/15 Truck 16 Truck 17 Truck 18 Truck 19 Truck 20 Truck 20/21 Truck 22 Truck 23 Truck 24/25 Truck 26 / 27 / 28 / 29 Truck 30 / 31 Truck 32 Light flasher

|

|

Construction Day 5

|

|

|

All the buffers are complete to the stage where the rounded end has to be turned and lastly a 5BA tap threaded into the other end. |

|

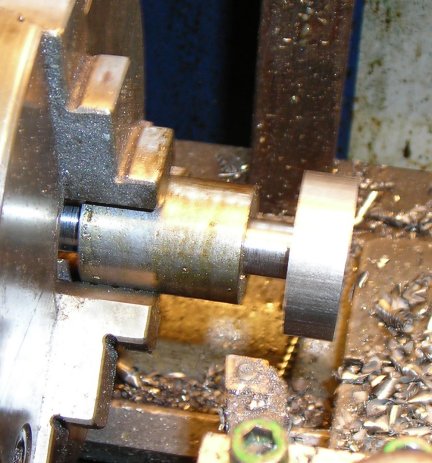

Here we have gone back a stage and I am machining the reduction in diameter which will eventually be threaded to nut the rear of the buffer to the truck |

|

Here the hole has been drilled that will take the 1/8" bar with the compression spring. |

|

Now I have turned the item round to drill in from the front. |

|

|

|

|

|

Hole drilled to take the front part of the buffer. |

|

The buffer fits the rear of the buffer |

|

Here are all 8 buffer nearly made. |

|

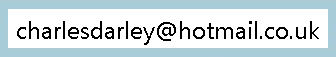

The setting up to put on the 2.5 degree taper. The piece could only be held by such a small amount that machining was going to have to be very gentle !! |

|

Now the rear of the buffer has been tapered by 2.5 degrees and all are very nearly completed.. |

|

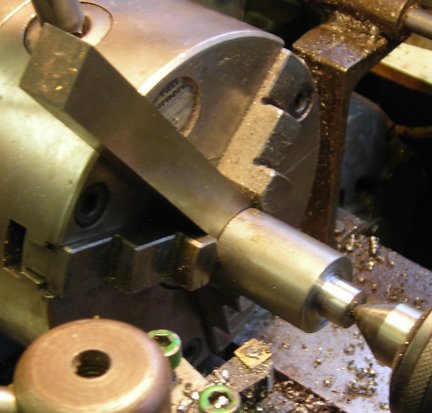

This is a technical picture as years

ago Paul and I devised this cam follower tooling to make the heads on the

buffers. Not our idea I might add but our representation of an idea seen

in an engineering magazine.

Usually the tool is held firmly and the top slide under control but here the top slide of the lathe is moved forwards, as it is wound back forcing the cam follower to move the top slide towards the head stock. The resulting action makes identical heads on the buffers. |

|

The buffer before the rounded part has been cut |

|

The buffer after the rounding of the head. |

|

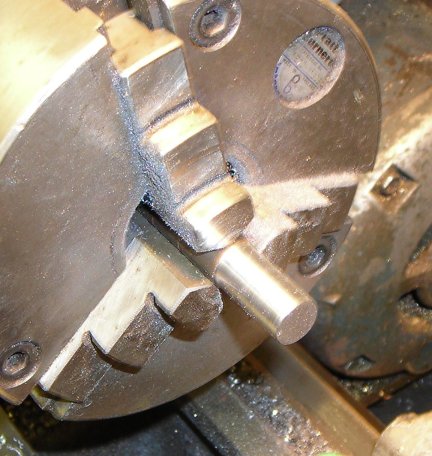

Machining carried out by Paul to remove just enough steel from the bar which is 1/2" to make it a sliding fit into a 12mm hole in the bearing. |

|

Here is success and a hole drilled in the end ready to tap as required by the drawings. |

|

Two completed axles with the bearing in position. |

|

The buffer beams have been cut.

They now have to be drilled for the buffer mounting and the tow hooks. |

| Total time spent in the

workshop to day is 8 hours a great deal more than was expected and then Paul

spent two more hours with me to night so you could say a total of 12

hours.

Decided to buy the necessary 6mm 8mm and 10mm taps and a 10mm die so that the construction can proceed. I have used my Ebay supplier who has been very good in the past but whether they will be here for the weekend I do not know. |

|

|

If you have any comments / questions about the project then please email me ...

|

|

|

|