The Diary of the Building of a Driving Trolley |

|

|

|

|

Driving Trolley build Truck 1 Truck 2 Truck 3 Truck 4 Truck 5 Truck 6 Truck 7 Truck 8 Truck 9 Truck 10 Truck 11 Truck 12 Truck 13 Truck 14/15 Truck 16 Truck 17 Truck 18 Truck 19 Truck 20 Truck 20/21 Truck 22 Truck 23 Truck 24/25 Truck 26 / 27 / 28 / 29 Truck 30 / 31 Truck 32 Light flasher

|

|

Construction Day 12

|

|

Mid morning start today .

|

|

|

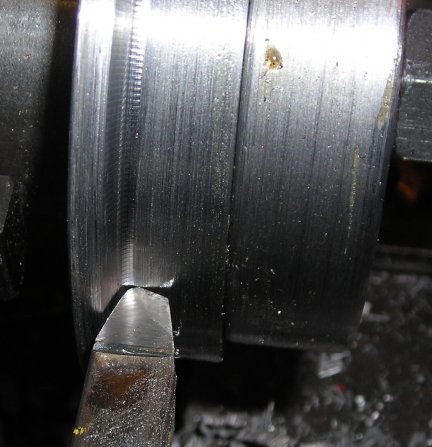

The wheel blank has been machined

. There is some chattering and I do not know how to solve that as I ran the

machine a gently as I could.

|

|

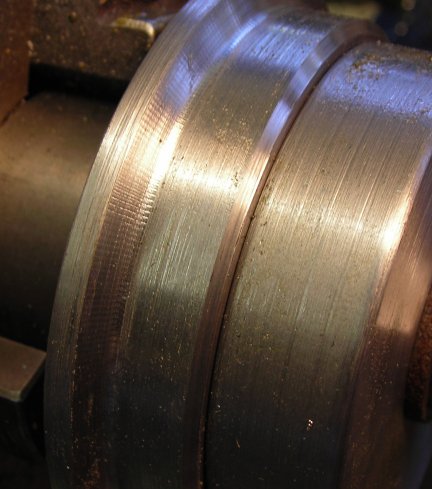

Here the wheel has been had the front angle also applied and the wheel is now complete - EXCEPT for tapping the securing bolt threads on the reverse side. |

|

All 16 wheels completed to stage mentioned above. |

|

Well not quite finished as they needed another 1mm taken off the flange to bring to gauge. |

|

Note the type of turning this is

due to the fact that a a very fine cut along the whole of the flange is being

taken to ensure uniformity,

Although no photo was taken the inside of the wheel where the axel enters was chamfered to ensure a close fit to the wheel spacer as it is rarely possible to machine two flush surfaces and not end up with a gap between in such circumstances. |

|

First set of wheels on a section of 5" gauge track |

|

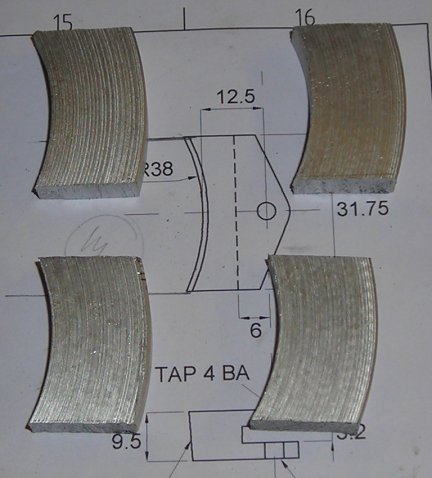

Looking at the plans i thought what

else needs turning as another part ready for the final assembly.

I saw the brake shoes had a curved surface. Then I found in the scrap bin a piece of aluminium casting that had held goodness know what and which I had been given years ago by my father in law Don Bruce. The casting was in fact much larger than the piece you see in the picture as I had to mount the piece in the lathe and scribe a semi circle and then drill and cut to make it fit the lathe. Still I know - well hoped that it would make the brake shoes. I machined it to size and then marked in pencil the lines you can see of the individual brake shoes and found that "YES" there was just enough material to make the brakes for the first truck. What I shall do for the second truck I do not know !!!! |

| So here are the shoes ready to have

the slot milled in the back side held in the vice on the milling

machine.

|

|

Not know which parts I

will receive on Boxing Day and not wanting to make what does come thus wasting

material I think it is necessary to turn attention to :-

So you can see there is still much to do but soon Christmas will be upon us and I will have to stop !!!!

|

|

|

|

|

If you have any comments / questions about the project then please email me ...

|

|