Diary of Building Katie from Roundhouse |

||||||||||

|

||||||||||

| 13th August 2011

A start was to be made on assembling the boiler. Used parts count 104 to include the parts shown in the picture However it was found that there is a second boiler band and that had not been painted. So painting took place to the boiler band and the smokebox. Another item that was found to need painting was in the body part kit and that was the Tank Filler Base. So this also was prepared and painted. |

|

|||||||||

| 14th August 2011

More parts painted from the Radio control packet. These have not yet been counted in the pasts count |

|

|||||||||

| 15th August 2011

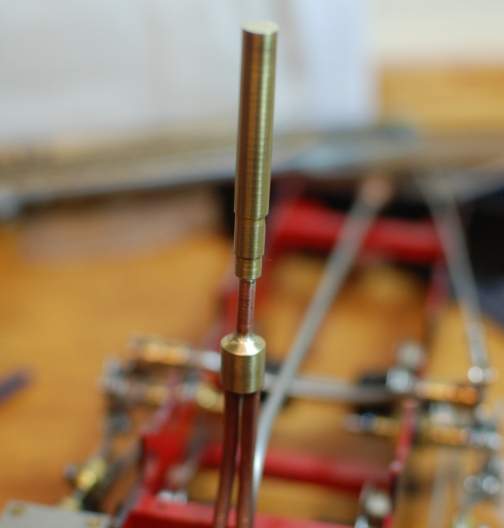

With the paint dry on the Smokebox the fitting of the "Chuff" pipe was under way with first the existing exhaust pipe being cut of to the predetermined distance given in the "Chuff Pipe's" instruction. |

|

|||||||||

| The ends of the pipes were cleaned

up with a file and the chuff pipe fitted. The out let is facing backwards

as recommended in the instructions.

Used parts count remains at 104 as the chuff pipe is not an original part. |

|

|||||||||

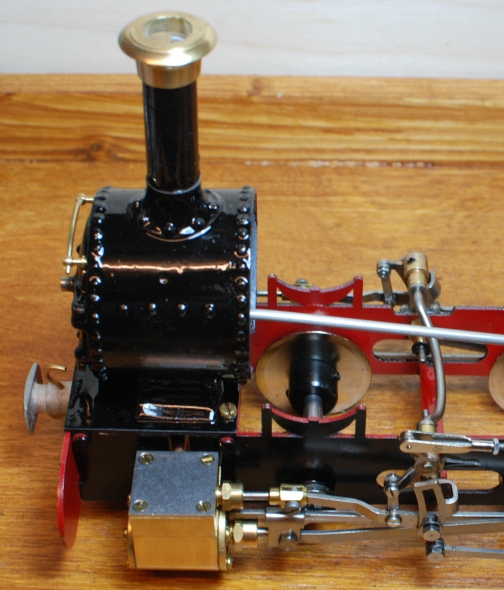

| The smokebox is now fitted.

Used parts count 105 |

|

|||||||||

| The boiler which had its wrapper

in place but not fixed was then slide into the smokebox and the foot of the

boiler secured through the floor of the body kit.

Used parts count 107 to include the screw to fit the rear of the boiler to the floor and the cab floor |

|

|||||||||

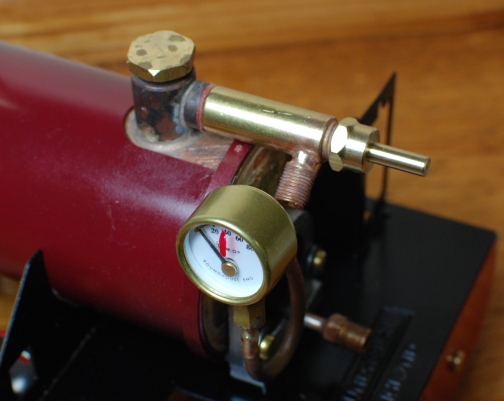

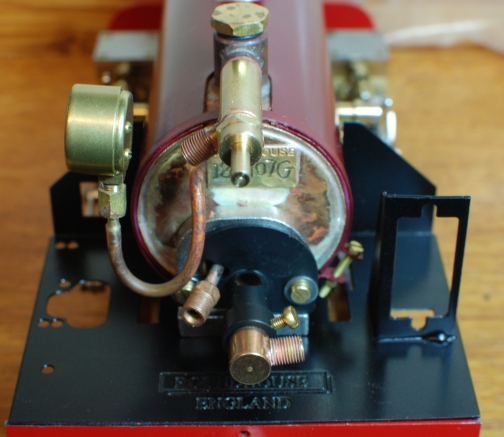

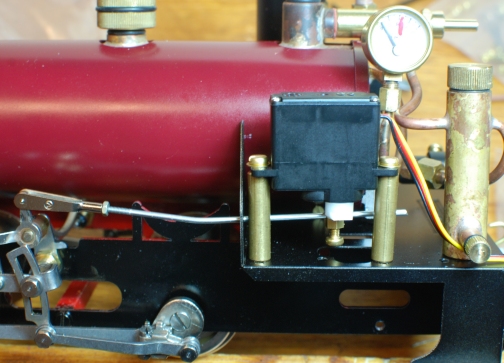

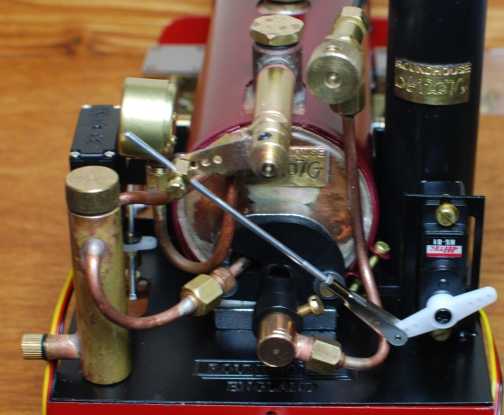

| Next to be fitted was the Radio

Controlled Regulator which is different from the manual regulator.

Also fitted is the pressure gauge and it has been marked with a red line at the max maximum pressure which is required when running on public / other garden tracks. Used parts count 109 |

|

|||||||||

| The burner was quite a fiddle to fit but was fitted in the end. |  |

|||||||||

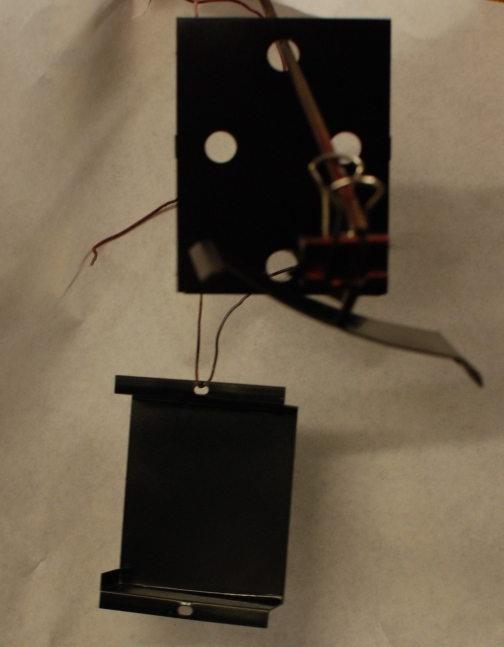

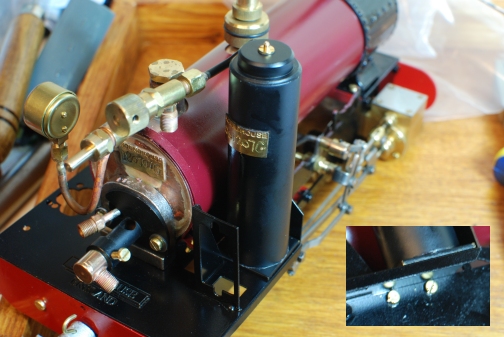

The gas tank was fitted and the insert shows the location of the bolts which are nutted the other side of the frame to hole the gad tank in place. Used parts count 114 to include the gas tank and two fixing nuts and bolts |

|

|||||||||

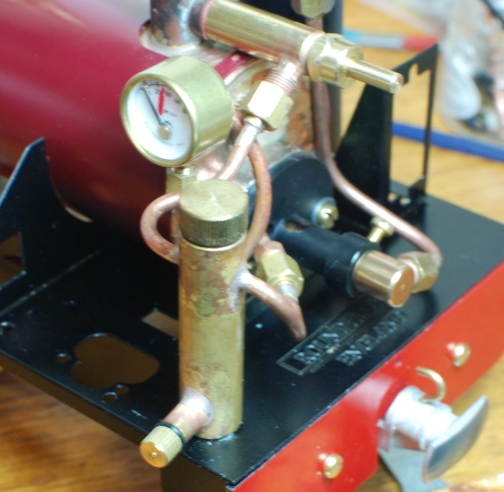

| The gas pipe was supplied straight

so it has to be bent into the shape to link the outlet of the tank to the

inlet of the burner. This was a relatively simple bending job but had

to be done without kinking the pipe.

Used parts count 115 |

|

|||||||||

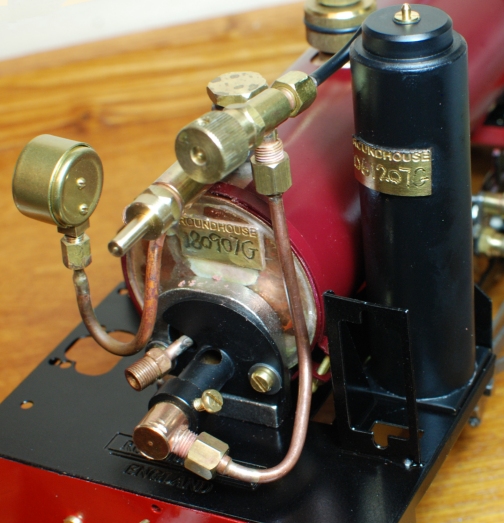

| The steam link from the regulator

to the "Super Heater Pipe" is made by the cylinder lubricator assembly.

Used parts count 116

|

|

|||||||||

| The forward and reverse servo is

now in position and set at its mid point.

Used parts count 128 not including the servo which was bought separately. |

|

|||||||||

| The regulator servo is now in place.

Fitting the lower nuts and bolt needed the use of some blue tack to hold

the nut on a screw driver end whilst a spade screw driver drove the bolt

home.

Used parts count 122 not including the servo which was bought separately. |

|

|||||||||

| And the loco is finished with the

fitting of the cab and some external fitting eg hand rails.

Used parts count 153 I THINK !!!! |

|

|||||||||