The Diary of the Building of a 5" gauge Stirling Single |

|

|

|

|

|

|

|

Completion of the build Part 25 |

|

| 14th

February 2020 I have 3D printed an engineer for the foot plate of the loco which was found on Thingiverse.com as in the image scaled to to the right size and have tried 3 different primers on my spare item (trial) pieces), Etch Primer, Craftmaster Grey Primer and straight acrylic paint.to see which undercoats the PLA material best. What fully dry I will paint the figure proper. |

|

| The

under coats results indicate that the acrylic paint does not set

and remains tacky, the dark grey needs more time but the Etch

Primer dried well. The figure is actually full length but the photo was trimmed to show the Etch primer in Grey, the lower part of the body, which when dry was painted over by blue acrylic paint which has yet to dry hence the shine !!. The figure is not of the period of the loco but a modern day engine driver to be in full blue overalls !! Checking much later the day the acrylic paint does set without a primer etc so for the real paint is will be no primer !! Not happy with Royal Blue for the overalls so obtaining a couple of other blue and a white so that I can make a custom colour!! |

|

| 17th

February 2020 In preparation of a steam test I decided to make a base that the tender could sit on and be stable so a piece of decking was presented to my router and two groves cut so that the wheels of the tender could sit in the groves and not on their flanges. Once cut a coat of varnish was applied and several more will follow to water proof the timber. I also recovered my submersible pump from my box of firings items and found that it has the same pressure fitting as I have used at the rear of the engine so I will be able to initially fill the boiler through the hand pump intake. |

|

| 18th

February 2020 Spacers were cut to length, the same as the angle iron supports to the rolling road and width to support the base shown above so that the tender was brought to the same level as the loco. The spacers were then screwed to the base and varnish applied to protect as far as possible from water damage !! The photo shows the loco and tender all assembled and wheels at the same level on the loco rolling road and the tender base. |

|

| The

scaled figure on the footplate looking casual and no hat !!! |

|

| 20th

February 2020 In preparation for a steam test my submersible pump connection box which joins two different cable together was fitted with a switch so that stopping the pump when filling the boiler was made much easier. |

|

| 21st

February 2020 With the very wet weather I have decided that I want to do a trial steam test in the workshop using a gas burner rather than having to do it out side in the cold 2 Degree C and wet. So I have made up a base board for the loco with and edge and also varnished so that any water and/or oil which may drop can be wiped off. |

|

| 23rd

February 2020 Testing the tender pump only to find that it did not pump. So the top had to come off and the pump given a light tape and water pumped through. As the top had three bolts which did not release but instead broke off I decided to make that dummies and painted them red to remind me .. |

|

| 26th

February 2020 The tender wheels needed their top coat of paint in light green. As they were all fitted they were painted in place !! |

|

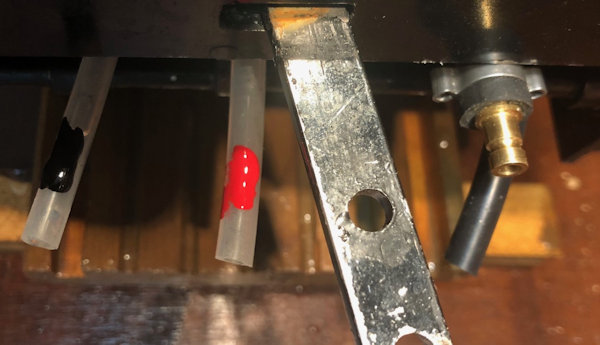

| One

of the fitting to take the black pipe on the right was reduced

in size to make it easier to slide the pipe on and the two on

the left were colour coded to make mis-fitting them more

difficult. |

|

| 1st

March 2020 The coupling between the electric pump and the loco was made originally with the diameter of the part entering the pipe too small and then when crushed down to seal left a tiny gap where water escaped from during filling the boiler under the pressure from the pump.. I increased the diameter of the part entering the pipe to 9.5 mm for the 8mm pipe and clamped it on. It works well and does not now leak. |

|

| 2nd

March 2020 Loco tested on it own steam from the boiler using a gas burner. I was only able to raise 30psi but that proved that the driving wheels went round and the whistle blew. |

|

| 3rd

March 2020 The loco was run up on compressed air to make the wheels go round and also proved that the axle pump was functioning as was the bypass valve. |

|

Next Page |

|