The Diary of the Building of a 5" gauge Stirling Single |

|

|

|

|

|

|

|

Completion of the build Part 24 |

|

| 1st

February 2020 this is the 202nd day since I restarted work on

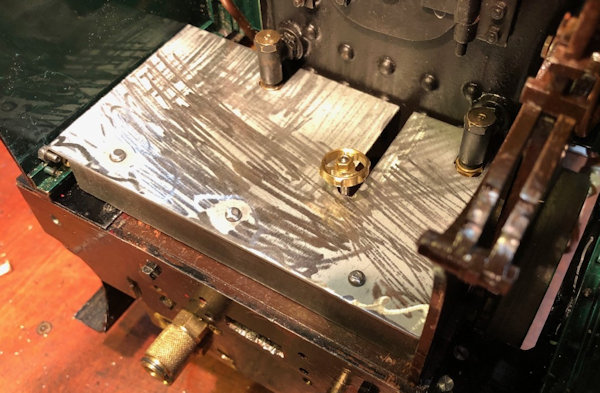

the loco in 2019 From the template the metal floor was cut and then the slots cut out. To make up the gap at the rear a piece of angle will be riveted on so that the floow can remain flush. The floor will also prevent the coupling bar from jumping out. |

|

| The

angle is now riveted to the rear edge and some of the paint

surface removed but I have decided to sand blast before sticking

the wood flooring down. |

|

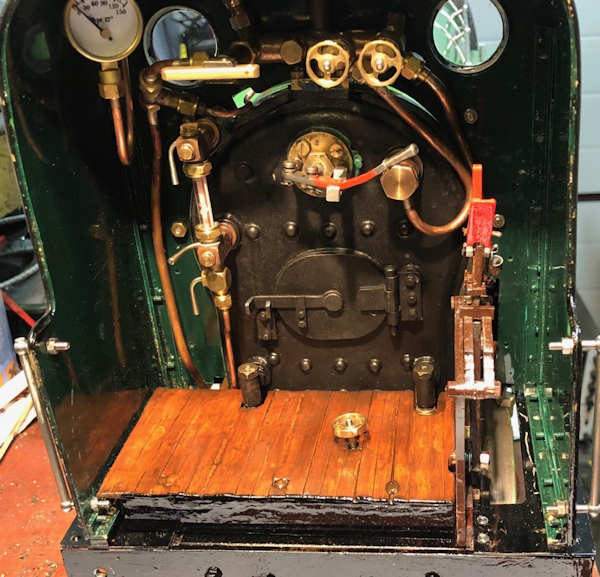

| 2nd

February 2020 The floor base was sand blasted and then the flooring which are used stirring sticks from my local café were super-glued into place. The excess ends will be trimmed off when fully set and given a coat of varnish. Chatting with my friends at the MMES club it was suggested that I do away with the slit and remove the bypass cock handle when I needed to remove the floor. This I have incorporated into the floor before I varnished it. The can of varnish says to use three coats well I will do that may be more as I have been told that hot steam and water can cause the timber floor to lift !!! |

|

| 3rd

February 2020 The floor has been given several coats of Teak coloured varnish to give it a dark appearance. Filling in the slot as suggested has given a much better look. |

|

| The

underside and rear of floor has been under-coated and will be

finished in black gloss paint and the "run" will not then be

seen. |

|

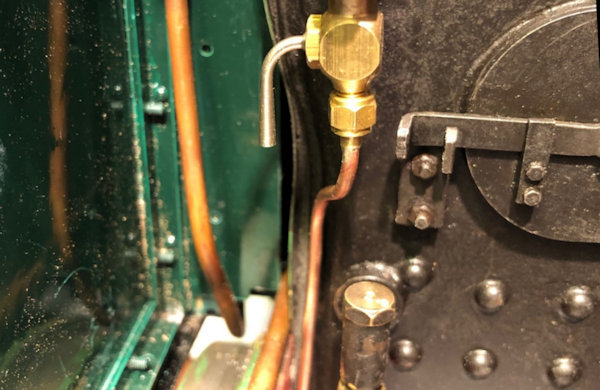

| There

is a piece of pipework from the blow down of the sight glass now

fitted and a notch out the floor not required as it fits behind

the edge of the floor which will be seen when the floor is

finally fitted. I have also reversed the side the handle for the drain down operates so that it is out of the way of the firing coal hole. |

|

| 4th

February 2020 Black gloss paint applied to the rear and underside of the floor and also to the rear of the drag beam. All looking very smart in my opinion!! |

|

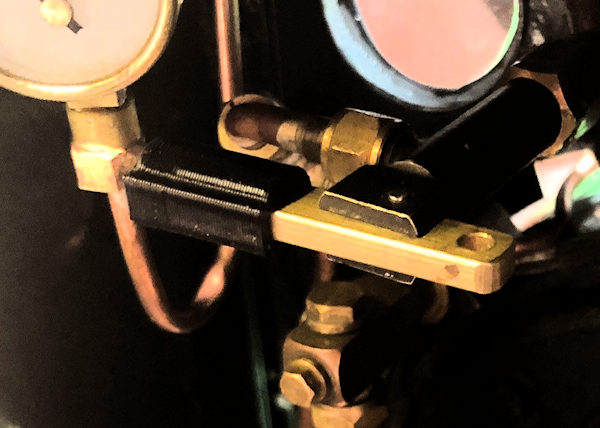

| 5th

February 2020 I drilled and tapped for a 4BA fixing into the stretcher immediately in front of the boiler, bent up a piece of brass and bolted it into position so that the blowdown could not fall down and cause a problem. Because of the difficulty in access I used a long bolt with and additional nut to make the job easier. |

|

| 6th

February 2020 In preparation for a steam test I located my rolling road which I made several years ago. They were made from a piece of old angle iron into which holes were drilled equally spaced and then the spacers made from bar stock and a thread cut into the end so that ball bearing races could be kept equally spaced and then a washer placed out side the bearing before being inserted into the angle iron. It works well. These will be used to support the loco and the tender will be supported on some timber. |

|

| 7th

February 2020 I had previously purchased from Amazon Empty Nail Polish Bottles with Dupont Brushes - 2x Sets of 6 - Clear Transparent Glass - Including Funnels (for Easy Filling) and Mixing Balls (for Better Mixing Results) - and used then to make up touch up bottles of paint for the Stirling Single The little funnels were so useful in aiding the filling and I used the top of the lid with its brush to indicate the colour. I have not yet inserted the ball bearing to aid the mixing as only just found them at the bottom of the packet !! |

|

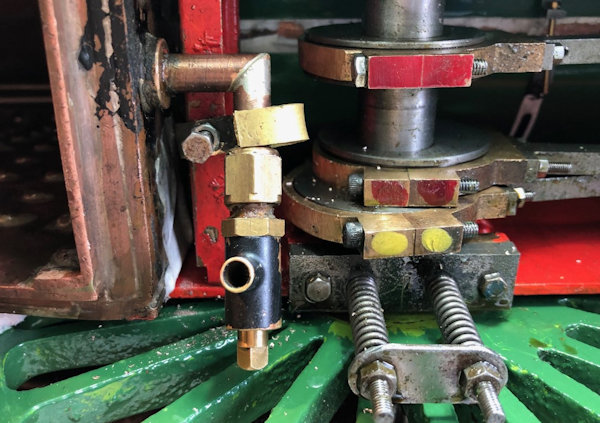

| I

have made a new axle pump by pass operator so that it will be

easier to see what position is it in, first effort on the 6BA

shaft so easy to make another if I want a different look !! The arm was silver soldered into place. |

|

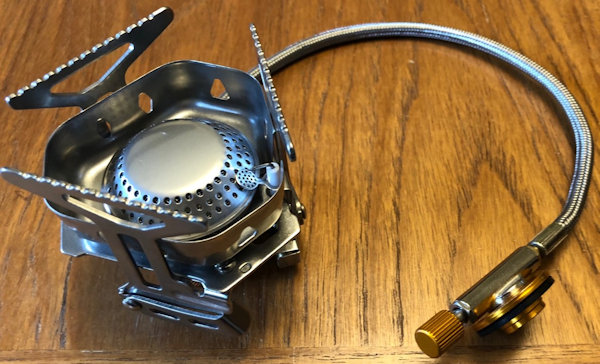

| 8th

February 2020 I made an attempt to run the loco on steam but the burner was too small, but a new one is on order. Click on the video and have your sound on!! However the whistle did blow even though if was only on 10PSIand steam also came from the dummy whistle, also steam went to the injector as did water and tried to reach the boiler. As all in all at.a good effort |

|

| 10th February

2020 The new burner bought from Amazon and the link takes you to my purchase. https://www.amazon.co.uk/dp/B07GTXRTLV/ref=cm_sw_em_r_mt_dp_U_NPwqEb8BKKJDP and now the gas can has arrived and the burner fits to the can very well and the auto lights well too. |

|

| 11th

February 2020 I checked out the calibration of the safety valve on air and set it as correct as possible ready for the steam test. |

|

| 12th February 2020 The gas burner fits nicely under the firebox and easy access to the lighter switch which is coloured RED. |

|

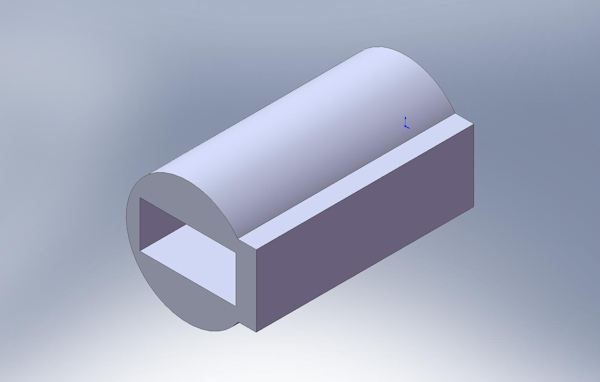

| Finding that on the previous steam test that the whistle press button becomes hot this is the drawing of a cover for the arm which I will 3D print and it should not melt as the 3D print needs a temperature of 220C to melt it !! |  |

| So from drawing to ready to fit in less than and afternoon. The press is a nice tight fit so we will have to see how it works on steam !! |  |

Next Page |

|