The Diary of the Building of a 5" gauge Stirling Single |

|

|

|

|

|

|

|

Completion of the build Part 26 |

|

| 6th

July 2020 After two unsuccessful hydraulic test at the club I have decided that I must amend the bobbin used for the regulator. The "O" ring whilst successful at a relatively low pressure it did not withstand the 120PSI for the test prior to stream after I have done a test pressure test and steaming at home. It has been suggested that I have used the wrong type of O Ring material and so I have bought the recommended ones of Silicon material. In addition to the O ring to be used to secure the opening end I may also need cut suitable grooves to hold two O ring on the bobbin and there by I hope restrict the pressure of water past the bobbin. |

|

| At

first the upright closer for the smoke box was removed and then

the four bolts which are 6BA / M5 were removed from the

regulator closing part The plate then closing over the regulator was carefully removed by first easing of with the bent part of a scriber and then with long nosed pliers. This revealed that the O-ring had been destroyed and was sitting with in the bobbin |

|

| When

the O ring was removed part of it was missing completely . |

|

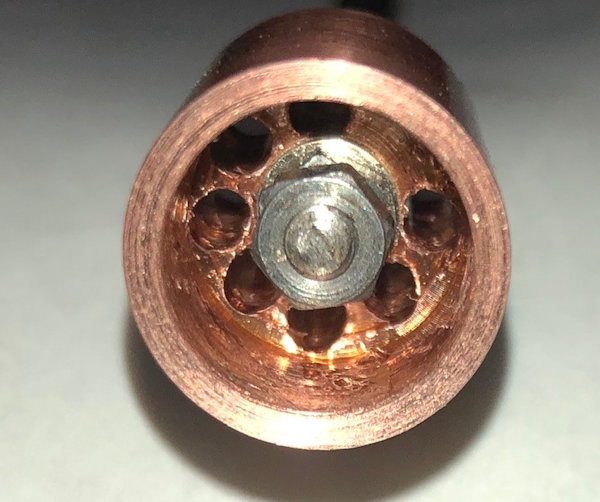

| The

size of the O-ring required is 5/8" but nearest I have is

is measured as 16mm. New O-ring (Silicon Orange coloured) 16 mm x 2.4 mm was installed |

|

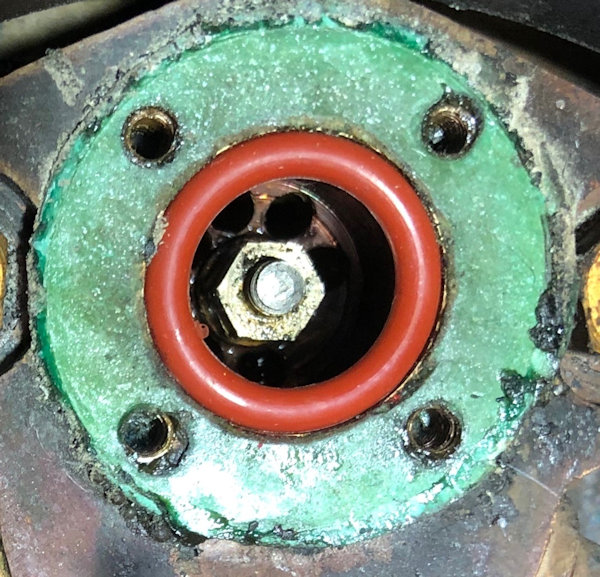

| 12th July 2020 In a Zoom contact with MMES friends during the covid 19 lockdown discussion took place about the "O" ring situation and I was told how the original failure might have occurred. This was thought to be due to the fact that there was nothing to keep the "O" ring in place and that I need to design a suitable fixing that would hold the "O" ring and also fit inside the regulator barrel. The amended cap is shown with a suitable recess to carry the "O" ring. |

|

| The photo shows the "O" ring fitted. |  |

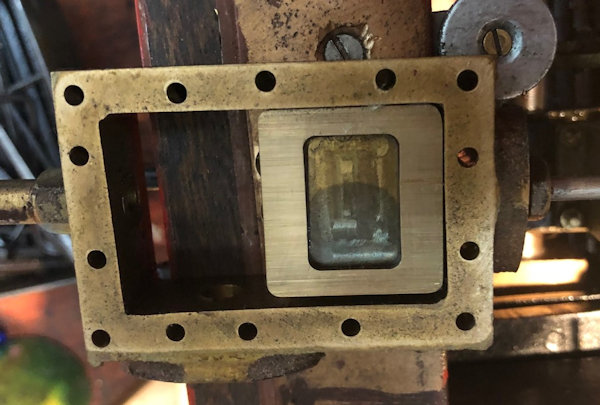

| To

align the cover it was necessary to use the scribing tool to

locate one on the holes thereafter the cover was pushed into

place by the use of fingers. The cover was replaced using the sealant and original bolts NB Very difficult to obtain a good photo inside the smoke box!! |

|

| The

bolts were tightened down with a torque wrench to 0.5 newtons. |

|

| 19th

July 2020 The loco was presented for a third for a boiler test and PASSED both Hydraulic and steam test on a very wet day. However when the loco went onto the track it failed to have enough steam to take it round the track. Steam was leaking from it was thought the front left hand side cylinder cover. |

|

| 25

- 28th July 2020 Work to solve the leaks was carried out including checking the slide valves, making new gaskets on my Cricut Maker and then a friend came round to carry out the bubble tests to ensure that the leaks had all been solved. They had and the worse leak had actually been a leaking union to the cylinder oiler not leaks from the cylinder covers were detected. |

|

| The

smoke box is refitted and the start of the sealing up to make it

air tight. |

|

Next Page |

|