The Diary of the Building of a 5" gauge Stirling Single

|

|

|

|

|

|

|

Feed pump |

|

| 24th July 2010

The eccentric for the axle pump was completed. When assembled onto the loco this will sit between the motion gear for the valves. |

|

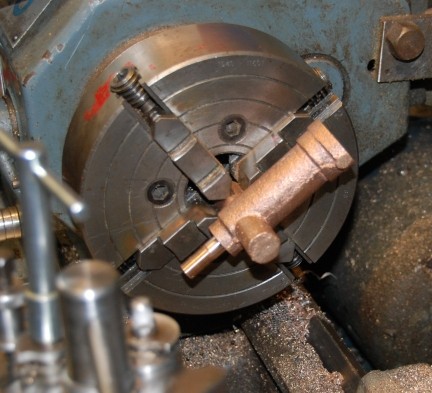

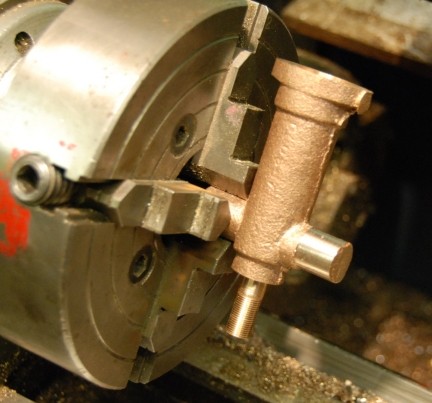

| Work was started on the axle

pump.

First the spigot on the end was set true in a 4 jaw chuck and then machined off for a reference. Then the pump was held by the spigot set true in a four jaw chuck and a hole drill and then bored out the size to take 9/16" stainless steel pump arm. Then the hole was further bored out to make a recess for packing. |

|

The pump was set up late evening ready to continue the machining the next day. The pump was set in the 4 jaw chuck so that it could be centered about inlet/outlet parts.

|

|

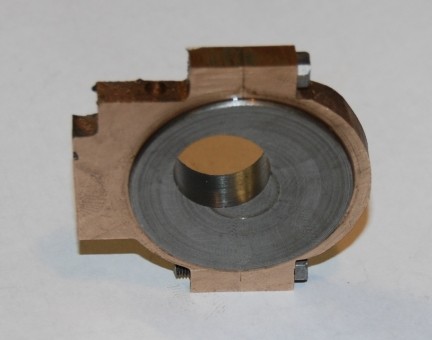

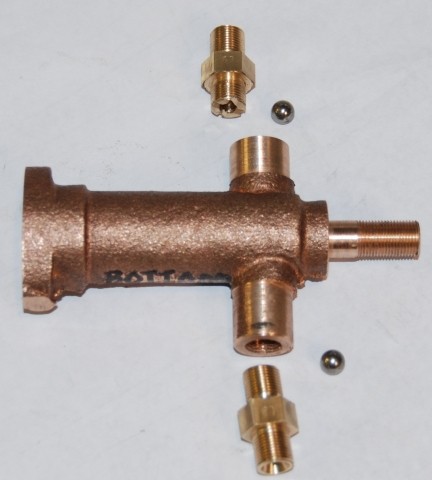

25th July 2010 Work on the axle pump continued. First a cut was taken to bring the inlet/outlet to round. Then it was turned end for end and put in a 3 jaw chuck and similarly machined, drill through for the port and then counter drilled to take the screw in fitting.

|

|

With that completed it was turned end for end again and the process repeated and here is the pump so far.

|

|

The inlet and outlet fitting were then made up from 1/2" hex brass and fitted with Stainless Steel balls. On the inlet side a STAR shape was filed into the seating in the pump's body to allow water to flow in similarly a simple cross was filed into the outlet seating to allow water to be pumped out as is shown below.

A simple test with a mild steel plunger proved all was well with the basic pump. |

|

26th July 2010 The pump inner Stainless Steel was machine from stock material.

28th July 2010 Today I was given a master class in using a slitting saw. I have never seen one operate before so I am obliged to my friend Martin who showed me how to use it and emphasised what a good asset it is to the workshop. Basically it is a circular saw on a substantial arbor and run as the correct speed for the size of the cutter which is basically the same speed as using a standard tool in a lathe and cutting a bar of the diameter of the slitting saw blade. In a matter of 20 minutes the stainless steel pump ram had its slot which drives the ram cut to perfection. |

|

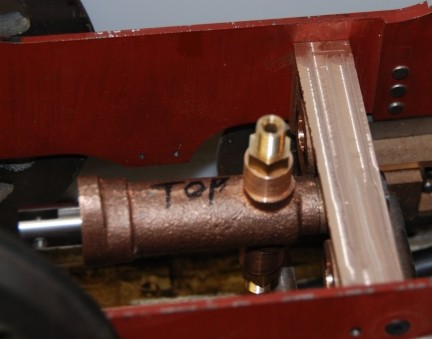

| 30th July 2010

The cross member has been machined and the pump has been attached. Next comes connecting up to the Eccentric but there is quite a bit to do before that !!! |

|

|

|