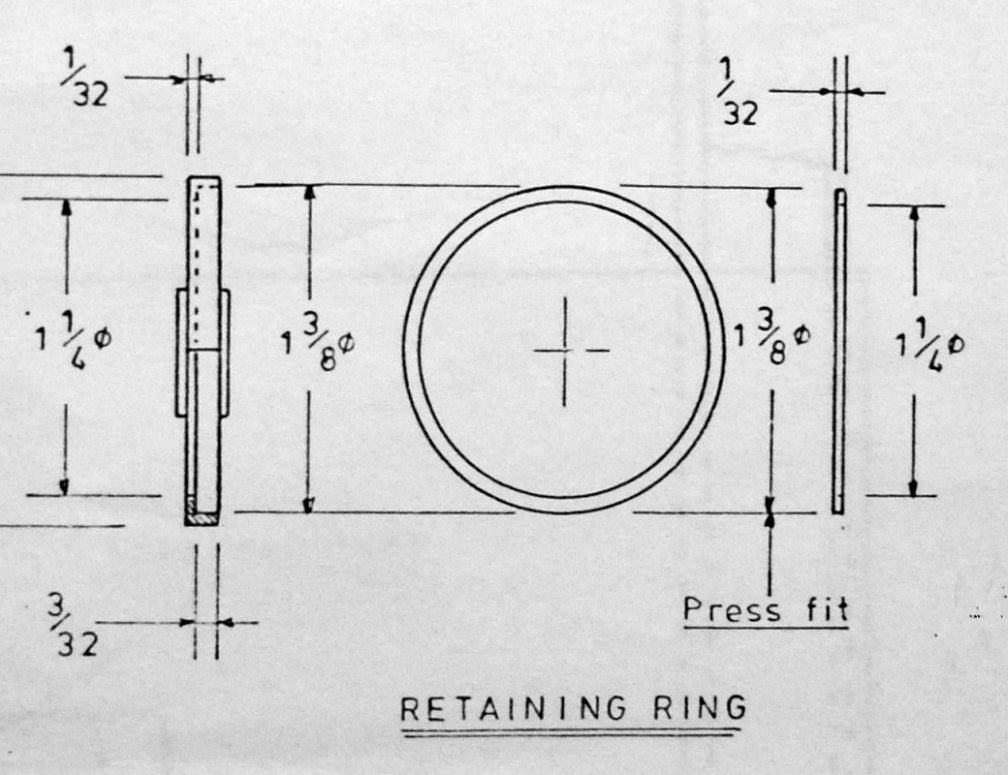

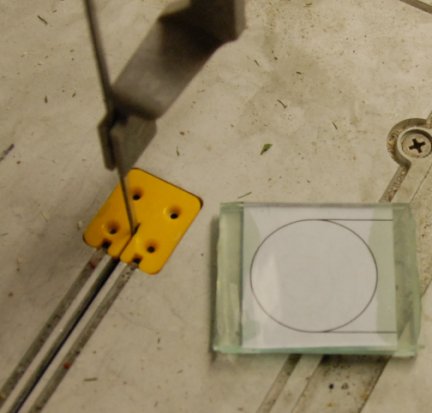

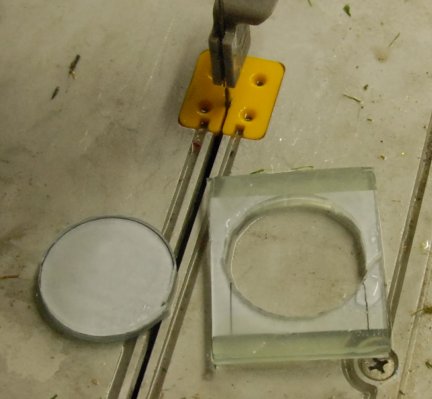

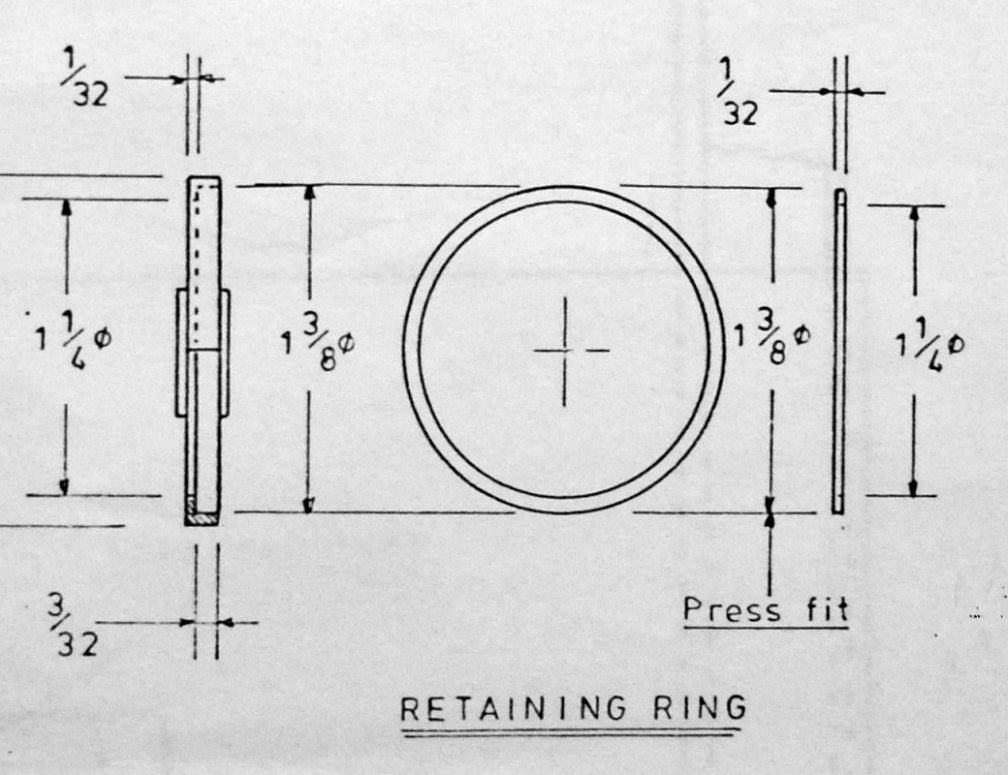

To do this I draw in the CAD package

the circle and printed it out 1:1 onto paper. |

|

|

|

|

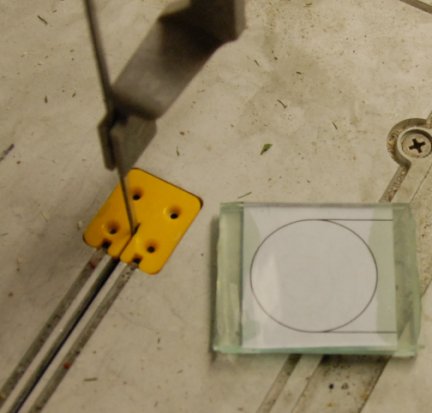

| I sandwiched the paper between two

over size pieces of glass having first applied to the left and right edge

Araldite Rapid.

The idea of using fast setting Alradite

was given to me by my close friend John Mallichan.

|

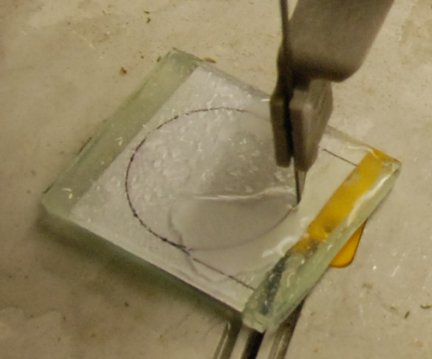

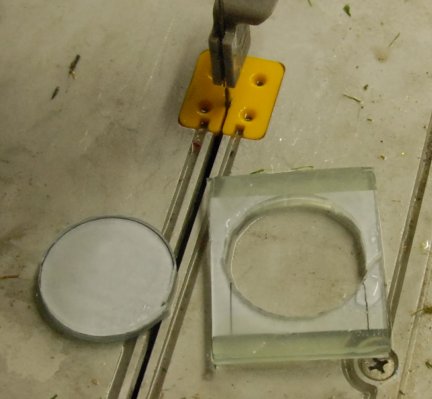

Having previously made

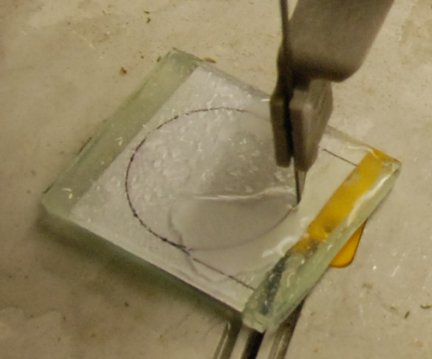

Stained glass windows I own a glass cutting saw so I was able to cut out

the two circles of glass at 34.5mm as accurately as possible |

Then with the diamond dressed grinding

wheel ,also from Stained glass days, I ground away the slight excess. To bring

to size I placed a fence 34.5mm away from the cutter and then used this to

bring to final size. |

|

| 20th July

2009

Visited

Western Steam

Model Engineers Burnham-on-Sea. TA8 1EY who I have commissioned to make

the boiler. It should be ready the end of November beginning of December

2009. |

| 23rd July

2009

Made the main axle a good fit to the

main driving wheels. Decided to purchase a 300mm digital calliper to make

accurate measurements more readily. |

This is my Stirling Single as current

with the main driving wheel with their axle and the training wheels needing

the axle to be made.

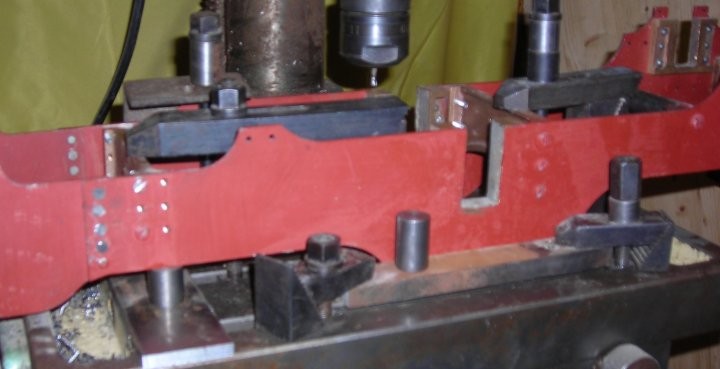

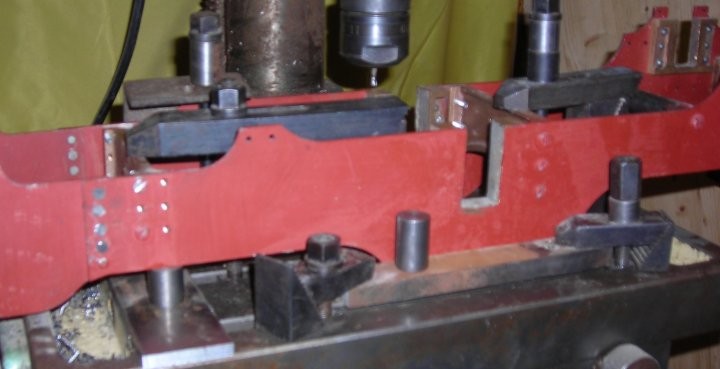

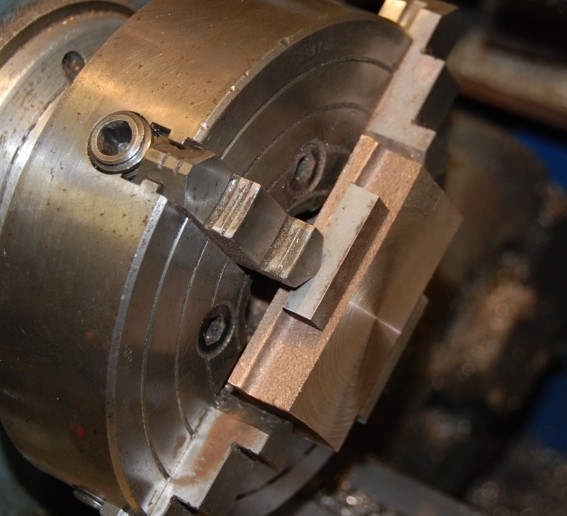

This evening I set about the task of

setting up the milling machine ready to cut the main wheel horn blocks. This

may not be the usual way but it was the way I did my Sweet Pea loco 20 years

ago and that is still running. The setting up took 2 hours!

The round piece in the centre of the

picture is the gauge for the width of the horn blocks. |

| 24th July

2009

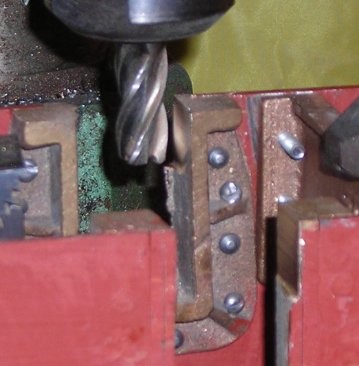

In the morning work started on the slow

and careful mill cutting of the main axle horns. |

|

|

Taking a limited depth of cut |

|

|

|

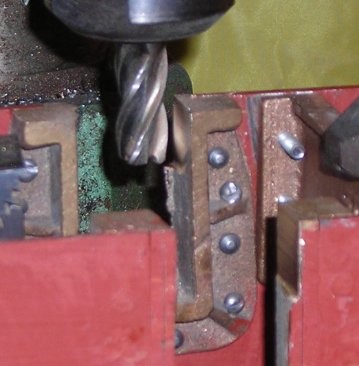

The cut has now been taken as low as

possible and the remainder has to be filed out! |

|

|

Having taken the cut as deep as the other

cutting tool would go I changed to a thinner but longer tool. Note the plastic

sheet as some protection from flying fine cut particles.

After quite some time the trial block

fits nicely and the job is done. |

In the evening of the same day

!!!

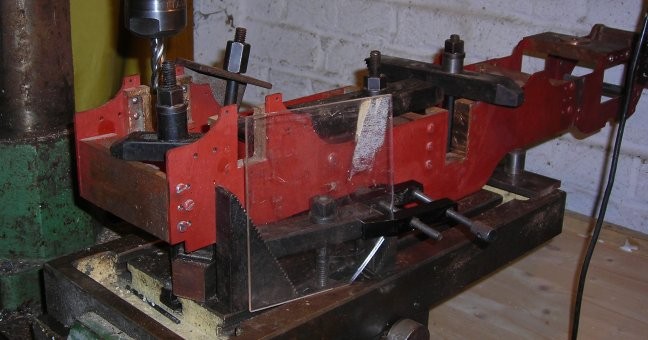

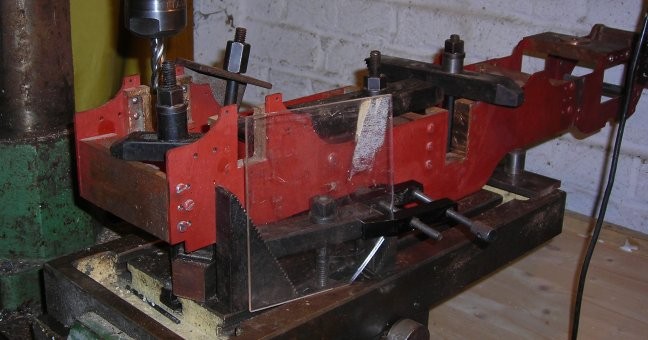

The set up for machining the last pair

of horn blocks. cutter was carefully aligned so that the frames were square

to the cut. |

First side completed as far down as the

cutter will go |

Both side completed as far as using the

cutter |

Compare this with the initial set up.

The additional clamping was to remove as far as possible vibration of the

frames. |

The completed horn blocks after filing

has been completed. |

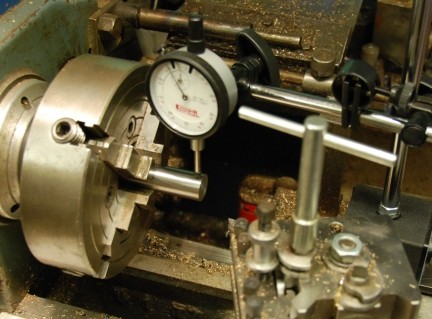

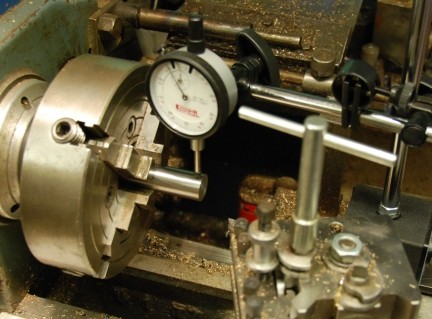

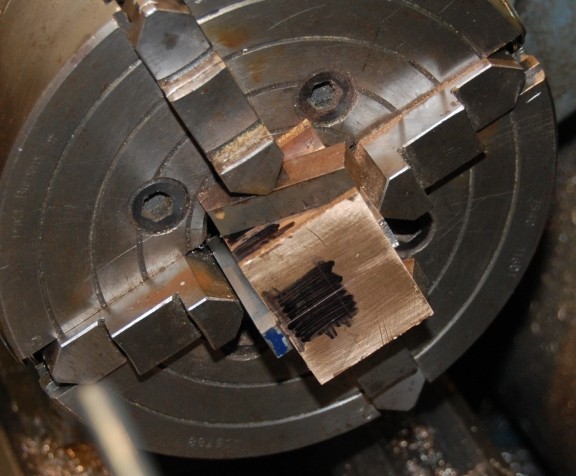

| 23rd July 2010

Made up the axle for the driving wheels.

To make sure that the axle runs true it is clock in a 4 jaw chuck until the

error is only very slight and of the order of 1/1000th of an inch.

The shoulder is then machined to size

and centre drilled. |

|

| Once one end was completed the length

of the bar was cut about 4mm over size pit in a 3 jaw chuck to face off and

then carefully measured.

With the measurement known the bar is

then set up again in the 4 jaw chuck, clocked for true centre machined back

to overall length, shouldered and centre drilled.

With that done the axle was tried in

the wheels and the fit was very nice and sat on the rail correctly. |

|

| Here the frames have been moved to

building jig and the cylinder put in place as well as the

wheels. |

|

| The main axle will hold the two sets

of eccentrics for the valve gear and the single eccentric for the axle

pump.

The eccentric are complete except for

the absence of the axle pump eccentric. |

|

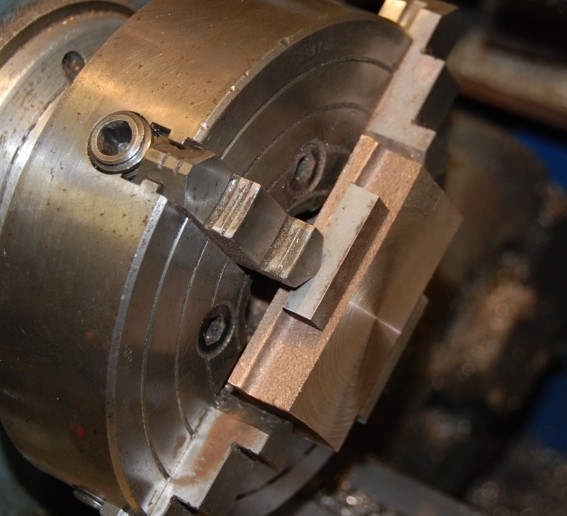

| 26th July 2010

Today the axle blocks were brought to

thickness (as shown in the picture) and then as with the other axle blocks

were machine to size of width to fit the axle horns and the correct amount

of step depth to the outside.

The block was then sawn in half and solder

flux applied and a small amount of solder and the two halves brought together,

aligned on the sides and then press down so that there is a zero gap for

the solder. A check round to find all was ok - this was done by

measurement.

The part now as one were placed in the

4 jaw chuck and aligned square and the top faced off followed by the

bottom.

Marking out then took place and the face

to be aligned with the laser pointer.

The drilling and boring will wait until

tomorrow or later when a check of the alignment will be made.. |

|

| This is how much has been done of

the loco .... |

|

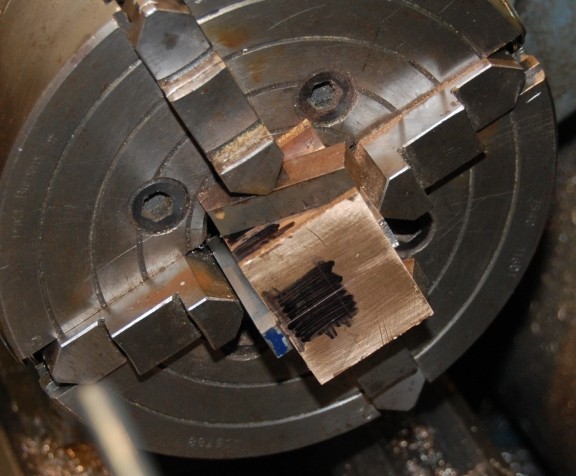

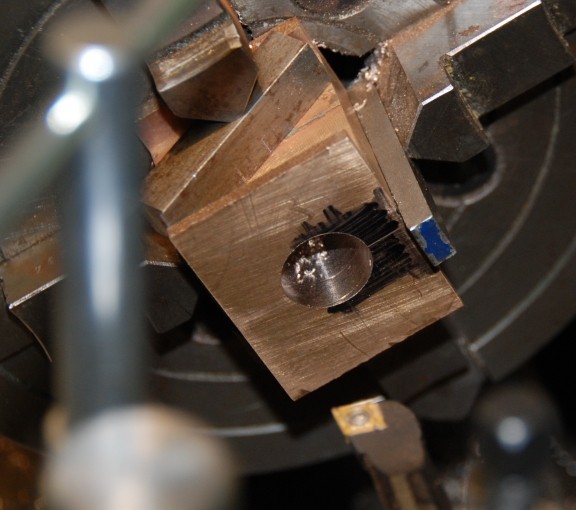

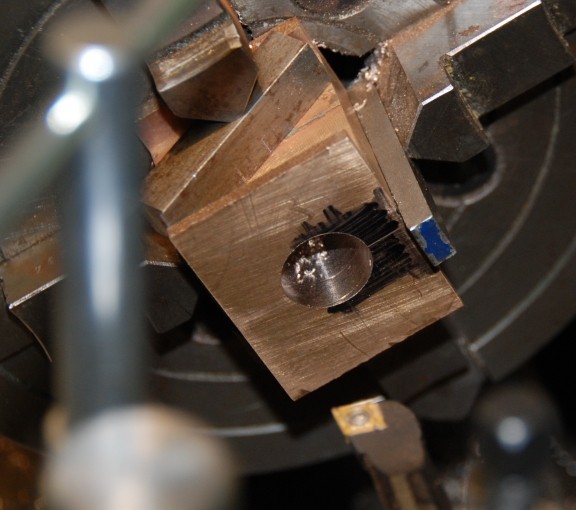

| 26th July 2010

The picture show the axle box set up

ready to drill and bore. |

|

| The first small drill has gone through

followed by a 1/2" drill and now ready for the boring bar to bring out to

size.. |

|

| The completed pair of axle boxes.

You can see the solder line on the sides. |

|

| The two boxes now separated. A great

deal of heat was required to melt the solder and the parts took a long time

to cool ready to clean up and complete the machining according to the

plans.. |

|

| 14th August

2010

Today I machined the trailing axle boxes

on their sides to fit the training horns and also to thickness over all which

leaves cutting the block into two and then drilling for the axle. |

| 15th August

2010

The axle box was cut in half, soldered

internal face to internal face, ends squared up in the lathe and then the

hole for the 1/2" axle marked out and then drilled. The reamer became stuck

in the final pass but with gentle easing moving the chuck against the reamer

it was removed and the hole then bored out to size. The reamer is to be thrown

away as it is blunt !!!! |

|

|

|

|