The Diary of the Building of a 5" gauge Stirling Single

|

|

|

|

|

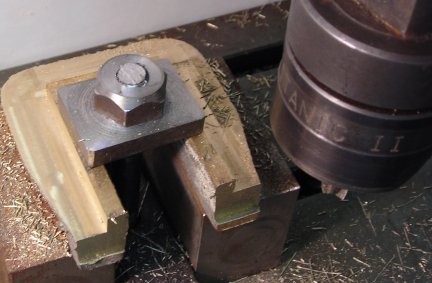

Main Axle Horns10th June 2007 The horn blocks need to be machined before they are fixed to the frames before the frames can be erected. The bolting face of the hornblock needs to the machined with an end mill so that it fits the cut outs in the frames and then can be drill ed from the frames and rivets into place with the rivet head on the inside and the outside hammered into countersinks on the outside of the frames. The inside faces of the horns are machined later. There are several sets of horn block. I decided to deal with the main horn blocks first. |

|

| It is very important that the horn

block is held down tightly onto parallel blocks.

The rear of the casting was tidied up on a face plate sander so that it lay flat and true. Then it was moved to the milling machine tightened down and milled. |

|

| The milling carried out so that it was a good fit in the cut outs of the frames and all that remains is for the flange to be brought to thickness of the frames.. |  |

The inside to the horn block fitting nicely in the cutout. |

|

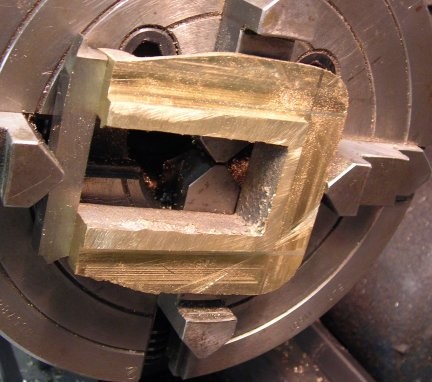

The horn block was then set up in the 4 jaw chuck of the lathe and brought to thickness of the frames leaving only a little filing for perfection. The next stage is to check over all thickness, clean up the outer edge, drill and tap for the keepers and then drill and rivet into place. |

|

|

|

|

|

|

|

|

|