The Diary of the Building of a 5" gauge Stirling Single |

|

|

|

|

|

|

|

Eccentrics |

|

|

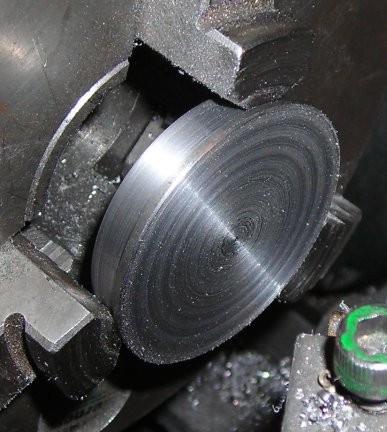

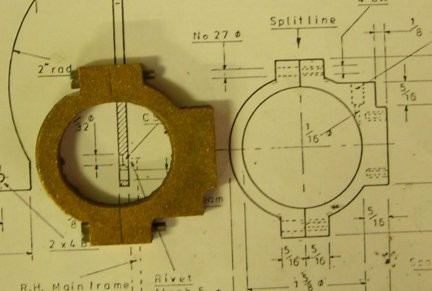

4th June 2007 Attention is now turned to the eccentrics of which for the valve gear there are 4 unit and for the axel pump one unit. The valve gear units will be shown first. First the blanks for the four eccentrics are cut of stock bar. I had some the correct external diameter !!!

|

|

| The blank was then faced off front and back. |

|

|

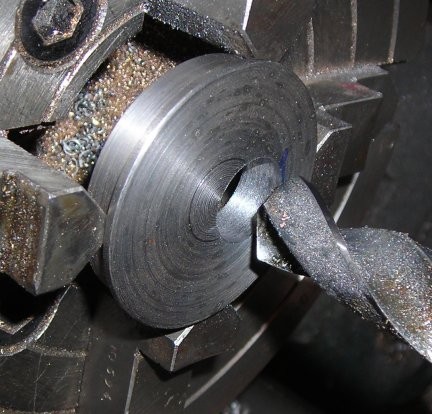

Then the amount for the depth and width of the eccentric machined. |

|

|

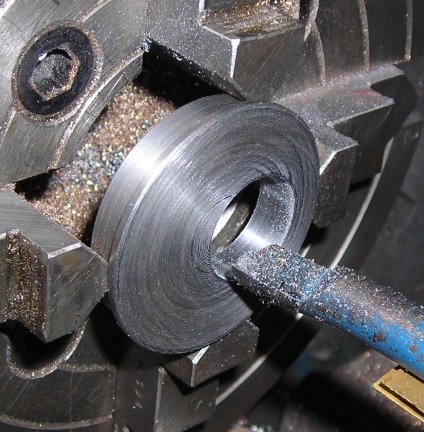

Lastly the item was turned round and the back faced off to the thickness for the edge. |

|

|

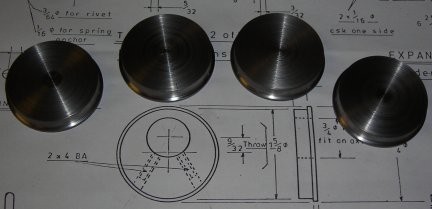

Here all four can be seen waiting for the off centre hole to be made. |

|

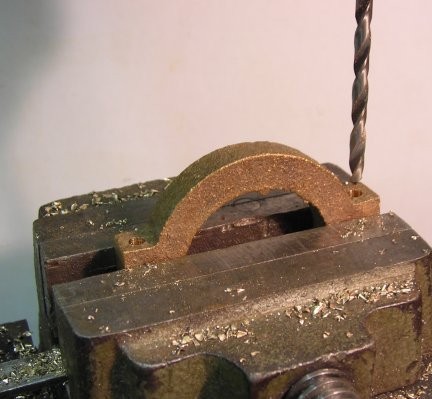

Eccentric StrapsThe first job to do on the eccentric straps is to generally clean up the casting so that there are clear sides at right angles to each other to hold in a machine vice and later in a 4 jaw chuck.

|

|

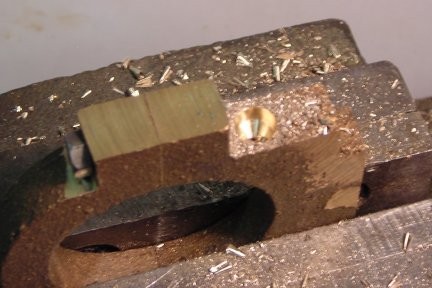

| With that done it is

necessary to set out the centres for the bolt holes and to drill

them with a tapping drill for 4BA which, in the correct part,

will be opened out to 4BA clearance and in the other part tapped

4BA.

|

|

|

Saw the strap in half where marked on the casting. This cut line then must be well bedded down by filing or milling removing the minimum of material to achieve square and true faces.

|

|

|

|

|

| Tap the appropriate side and clearance drill the other for the 4BA bolt. Pass each item across fine wet and dry paper to take off any burrs | |

|

Bolt the two parts together the measure and mark for drilling for the oil way (as drilling into and open hole is likely to break a thin drill). The strap is actually the wrong way round to agree with the drawing !!!!

|

|

| Cut off the end of the bolt

ready to drill for the oil reservoir.

|

|

| About to drill !! |  |

| The hole is drilled for an oil reservoir with smaller feed hole

beneath.

However I have been told that it is best to drill the oil way after the machining !!!! |

|

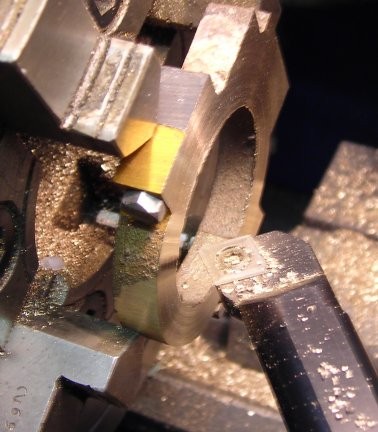

| 6th June 2007

The strap is now ready for machining the face sides. The machining must leave equal material on each side of the bolt fixings. Here the first cut is about to be made.

|

|

| The last cut has been made.

See how close to the bolt head the cut came !!!

Before the boring took place a check was made that the existing hole is central up and down and left right so that the bored hole will be central and must be bored to size of a nice running fit with no slop. Test by using an eccentric. Keep the units in pairs just in case there are any slight differences. |

|

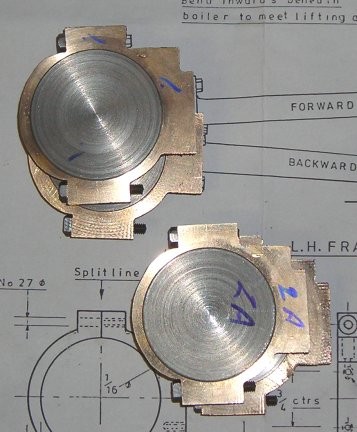

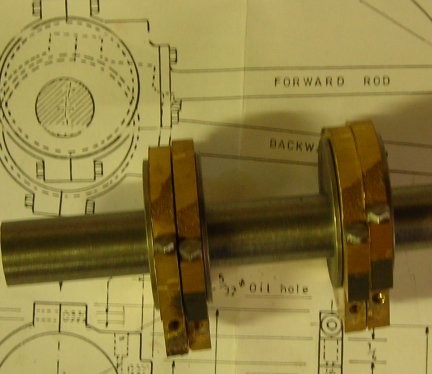

| The four sets of eccentrics

with their straps as finished except for the off centre hole.

The fifth eccentric and strap have to be machined for the axel pump. |

|

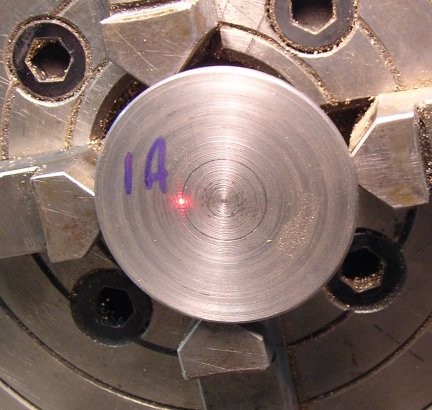

| 7th June 2007

To find an accurate centre a small length of bar was placed in the chuck and the tool moved across. The tool was set a fraction below centre so that a "pip" remained. This marked the centre point. The tool was then moved out the 9/32" required and the measurement checked. |

|

| The eccentric was then set in the lathe and a fine line scribed with the tool. |  |

| A Laser pointer then was set

up in the tail stock and the jaws of the 4 Jaw chuck adjusted so

that the laser point fell on the line.

It would not have mattered where on the line the laser had located as all points are the correct distance for the offset to the drilled and bored. |

|

| So centre drill first |  |

| Then a 3/8" drill |  |

| Then a 9/16" drill |  |

| Then the boring bar to bring to size. |  |

| Here are the two sets of eccentrics for the valve gear so only have to tackle the axle pump one now. |  |

| 11th June 2007

The machining of the axle pump eccentric is generally similar to the other but first a longer piece of stock bar was cut and then using a parting off tool the recess machined to size for the eccentric strap. The end was faced off to the thickness of the supporting edge. Then the three jaw chuck had its jaws revered so that it would grip the piece against the face of the jaws to reduce the over sized cut of bar to the thickness of the edge. |

|

| 11th

November 2015 I am now making a trial assembly of all the eccentrics and had to file to fit the extension to the pump eccentrics but they are all in place in the photo. They do look out of alignments but that is due to the camera angle. |

|