The Diary of the Building of a 5" gauge Stirling Single |

|

|

|

|

|

|

|

Smokebox Part 2 |

|

| 21st

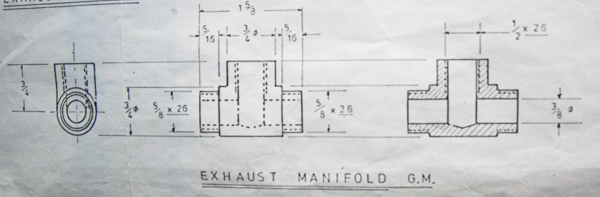

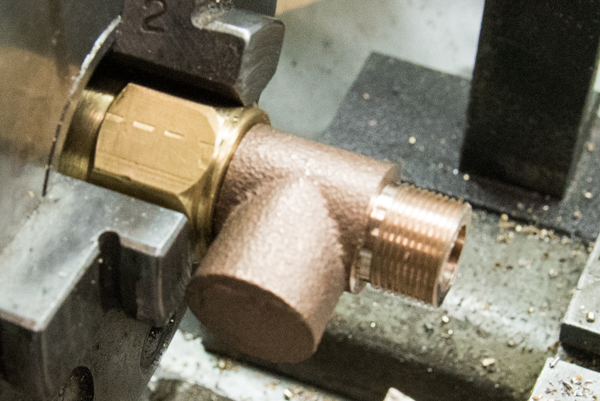

November 2017 An interesting piece to make from the casting as the threads are so big 5/8" x 26. So the first part to make was something to hold the piece after thge first end had bee threaded. I was fortunate to have a large piece of brass which was previously a bung for the safety valve to this was threaded as needed. |

|

| Here the piece is

being held in the threaded brass piece made as mentioned above. So already one end had been machined down to the threading size and then threaded and drill half way through. It was then reversed and oput into the threaded part as shown and the other end completed and also drill through to meet the first drilling. Just as the holes were to meet I reduced the size of the drill to make an easy breakthrough and then went through again with the 3/8" drill. The reason for drilling from each end was to eliminate as far as possible any off centre drill hole so that when the pipes are installed there will be a clear flow of exhaust steam. All that remains is to mount the part in the mill ready to carefully cross drill and thread for the blast nozzle. |

|

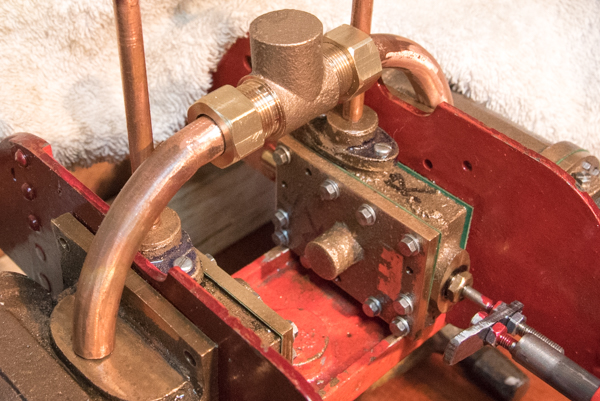

| 26th November 2017 Today I made up the nuts to fit the centre piece shown above. The bent pieces of pipework had their end flared but I then found our that the nut would not tighten them to the centre part. I made up two brass washers to take up the slack and so far the positioning of the assembly looks promising. I now need to workout the position of the blast nozzle and then drill the parts which will be bolted to the exhaust ports accordingly and then silver solder them prior to bolting down. |

|

| 27th November 2017 The exhaust manifold was centred in the lathe and centre drilled and then topping drilled for 1/2" x 26 tpi. The hole was threaded and the outside finished to make it look better. Then after all the effort I put in to find my original Blast Nozzle When I tried to fit it I found that the plans had a different thread than the thread into which it was to screw. So a new blast nozzle was made up and fitted to the manifold as shown in the photo. |

|

| 28th November 2017 The link to the cylinder was marked and drilled and then silver soldered to the pipe. |

|

| Now both sides have

been silver soldered. Even with trying to drill at the correct angle a little linishing may still be required to bring the mating surface together I will look at that after the bolting down has been completed. |

|

|

|

|

|

|

|

|

|

|