The Re-boilering of Baudot 8187

|

|

|

|

|

Main Index Boiler index BAUDOT RE-BOILERING Page 1 Page 2 Page 3

|

|

Day 1-- the initial boiler test 31st March 2010 Late in 2009 I had a new boiler made by WESTERN STEAM Model Engineers. On 31st March 2010 I took the boiler to the MMES (Maidstone model Engineering Society) for a once over and repeat of the hydraulic test to obtain a 4 year certification rather than the 1 year as provided by the boiler maker. The testers were very pleased with the look of the boiler so all credit to Western Steam for a great boiler manufacture. The test was passed and certification achieved. This now gives me, should I need it 4 years to put the boiler back on the loco!!! |

|

| Day - - 2

30th Jan 2012 Finally the locomotive has been moved into the workshop maintenance area so that work can start. An electric hoist had been installed to make the lifting much easier and the bench is made of square section tubular steel all welded to give it substantial load bearing. The locomotive now needs to be stripped down and the new boiler put into position and then consideration given to which parts need to be re-made. Rather a mess in the workshop but it will improve as no good work could be done in that place and in that condition. |

|

| Day - - 3

31st Jan 2012 The first thing that had to be achieved was a turn table so that both sides of the locomotive could be worked upon with out heavy lifting. A turntable such as is used to support televisions / monitors was purchase which is capable of supporting a load of 100kgs / 200lbs approximately. Some reclaimed decking was then linked together and the turntable made which does a very satisfactory job.

|

|

| Day - - ;4

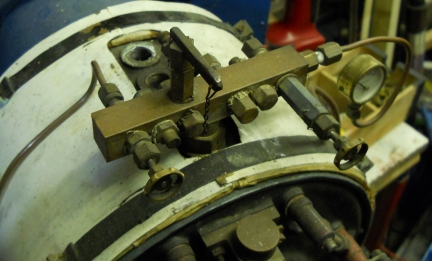

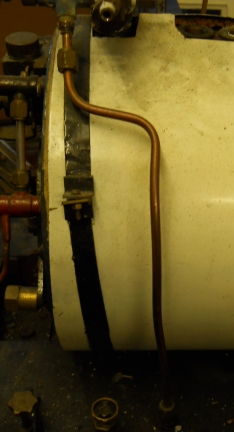

2nd Feb 2012 Very cold in the workshop so only a couple of hours spent in there but quite a lot achieved. Roof to the cab removed - whistle disconnected and removed - Connection to the right hand water tank removed - 2x 6BA nuts and bolts removed to release the cab in one piece ( the 6BA nuts and bolts put in bag marked 1 - 2x safety valves removed - released blower pipe - removed pressure gage pipe and gauge - released injector pipe from manifold and from floor and removed pipe - Removed the turret. |

|

|

|

|

|

|

|

Click for next page. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|