The Diary of the Building of a 5" gauge Stirling Single |

|

|

|

|

|

|

|

Completion

of the build Part 2

|

|

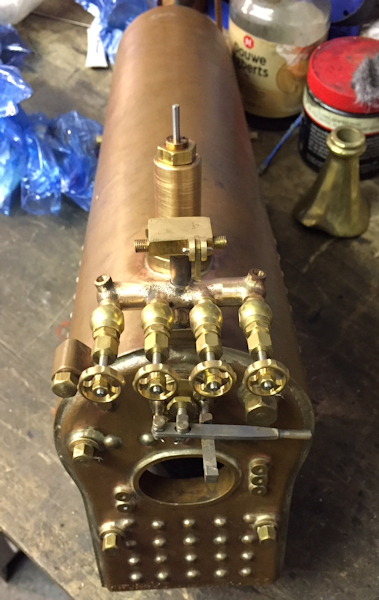

| 6th

June 2018 Some pictures of a little bit of progress. |

|

|

|

|

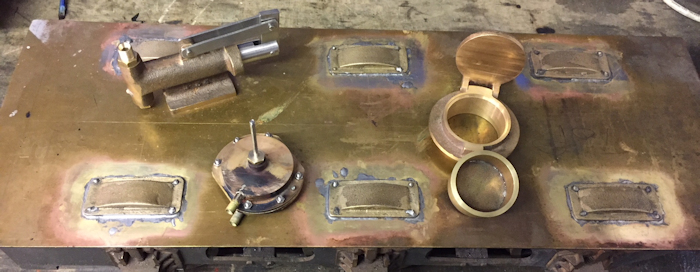

14th

April 2019

The

loco back on my workbench showing more of what has been

carried out.

I

have ordered a new set of plans from Reeves so that there is

no delay in me starting work.

|

|

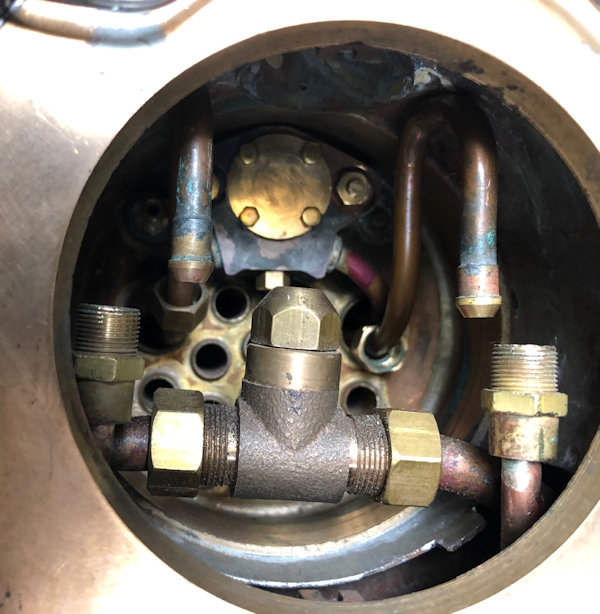

| Inside

the smoke box is very tight as the photo shows and again I need

to learn what is happening in there ... |

|

| The

splashers on the wheels look great but I will need

remove the rust prior to painting. This rust removal will be done in my Sand Blaster. |

|

|

15th

April 2019

With the loco on the bench I took a look to see what's what a list out things that were obvious to do. for the loco 1. the regulator does not operate 2. Sight glass fitting need aligning and glass fitted 3. Make the boiler door catch and fit 4. Sort out the coupling to tender 5. Fix chimney to smoke box 6. Amend the fixing of the cover plate above oiler 7. Sort out axle pump as will not fit under the boiler. 8.

Provide the blower outlet in the smoke box

9.

Seal up the bottom of the smoke box so that a vacuum can form

to draw the fire

10.

Fit lugs on the side of the boiler where it will sit on the

frames adjacent to the firebox.

Tender

1.

End caps for the axle boxes

2.

Coupling to main engine

3.

Sort out the pipe work to connect Tender to the main engine.

|

|

|

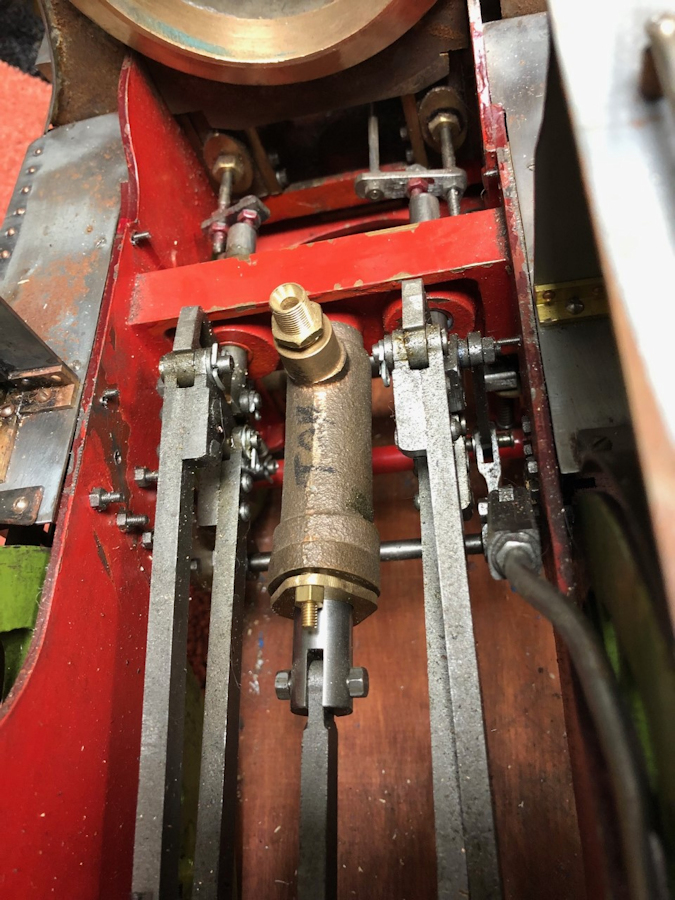

The

smoke is removed to show the oiler and the two inlet pipes

which when coupled to the boiler to allow steam in to the

steam chests.

With

the smoke box removed I can sand blast it fit the chimney and

then spray paint with high temperature paint.

The

axle pump has now been removed to start the amendment so that

it will fit under the boiler.

I

am considering cutting down the top of the pump and making a

right angle fitting to more economically use the space

available.

|

|

| The

water filter was just a little tight in the fitting so a very

fine skim was taken to make a satisfactory loose fit. |

16 16 |

|

16th

April 2019

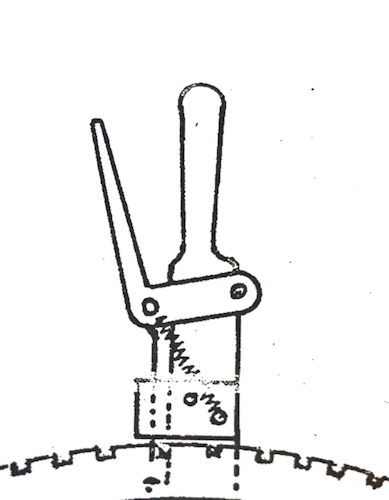

Not feeling up to doing any critical work on the loco so working on the plans and what tooling I need to make the little handle for the reverser. The

lever part is about 1" so a great deal of fine filing and

milling to do let alone drilling some very small holes !

I

shall for the rest of the day work out if I have materials and

milling cutter to achieve this item and also what size spring

is required !

|

|

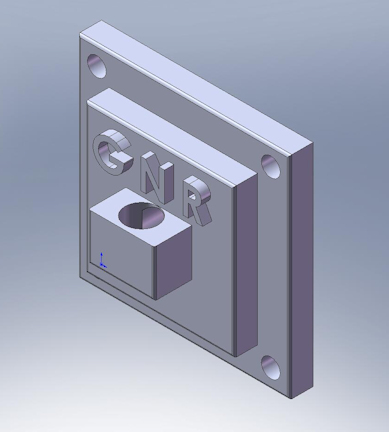

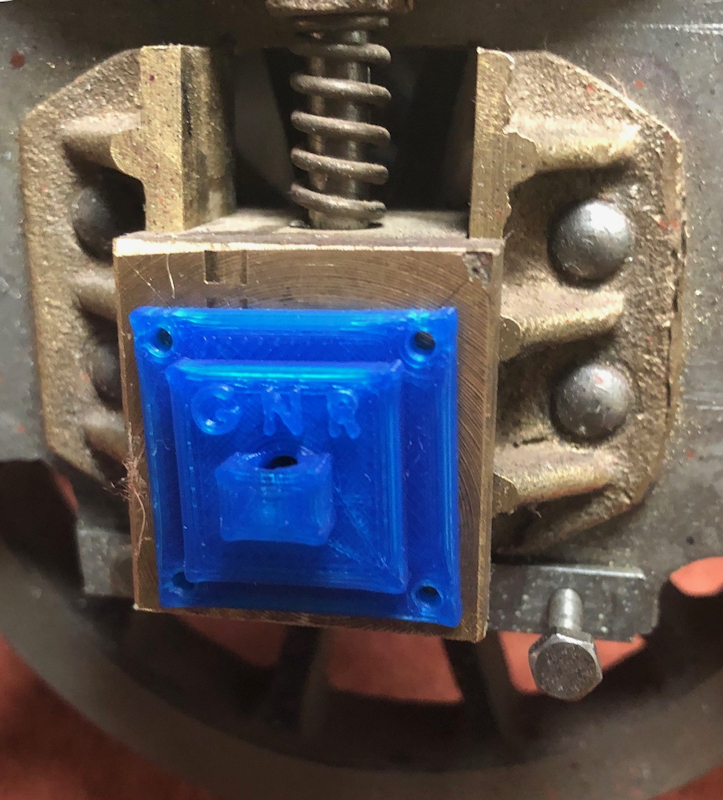

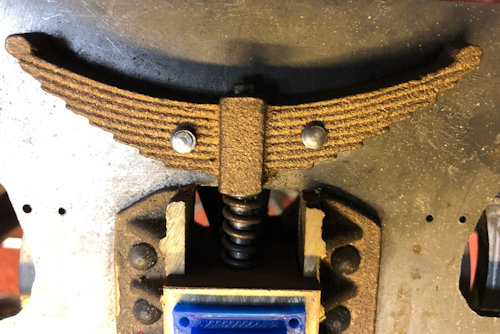

| Having

a 3D printer I decided to draw up the 3D STL file of the

Axle Box covers with oil ways. The 6 covers will take about 2 hours to print and the they will need to be painted and fitted. |

|

| 17th

April 2019 Over night I 3D printed the axle box covers and they are now ready to attach to the axle boxes. As they are to be painted I used PLA filament and the print time was about 2 hours on my Creality Ender 3 3D printer. The fitting have an oil way so I can oil the axle bearings. |

|

| 18th

April 2019 The axle box end covers were super glued into place and are now ready to be painted. |

|

|

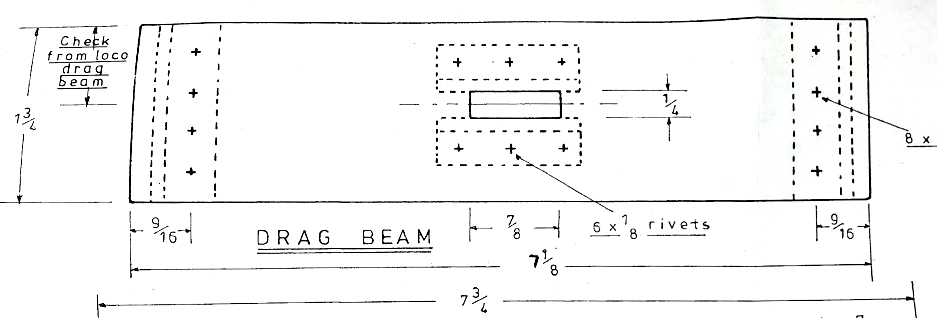

When

I made the Tender chassis I did not have the loco chassis

completed so I did not know the dimension which on the drawing

said "Check from the Drag Beam of the Loco."

So I checked the dimension and marked it out, drilled three 6 mm holes and the use a small file to join the holes and the a bigger file to finish to size as shown in the lower photo. There

was not enough time today to make up the pair of brackets as

seen in the drawing lower down.

|

|

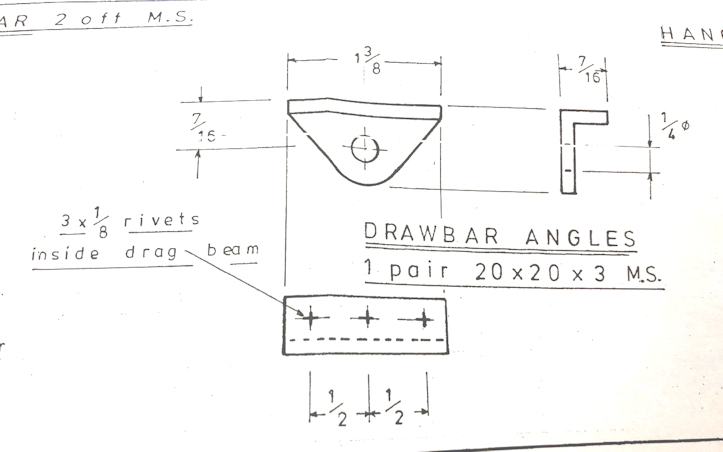

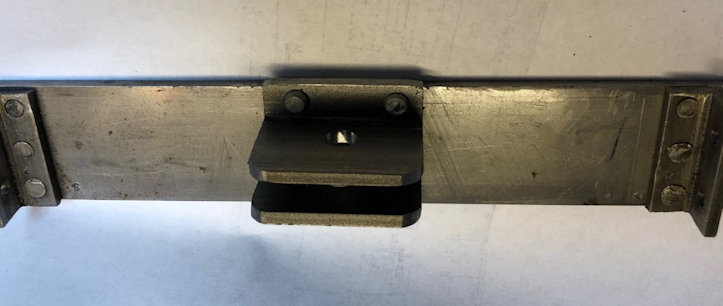

| 19th

April 2019 So today is the making and fitting of the drag beam drawbar angles. Two pieces of angle were cut from stock, reduced in size, and the drilled for the fixing rivet holes and coupling. |

|

| The 1/8" rivets were

then cut to length and outer holes counter sunk and the parts

joined by the rivets. |

|

| Finally a drill was put through to slightly widen the coupling hole and the unit refitted to the Tender Chassis. |  |

| 20th

April 2019 The lamp bracket on the cover for the cylinder oiler was made captive to the chassis by the bolts holding the lamp bracket. With the lamp bracket bolts removed the plate could be removed so I decided to rivet the lamp bracket into place. |

|

| I needed to recess the

holes so the the rivets did not make the plate covering the

oiler proud for the remaining parts. |

|

| To drill the coupling

holes in the loco drag beam I had to devise a long drill by

drilling out a piece of bar by the drill to drill the hole and

then using engineering adhesive 603 secure the drill into the

bar. The resaon for this is the with the regulator inplace when the loco was returned to me it would need to be removed to drill the hole. The drilling was a slow process may be my drill was not sharp but in about 15 minutes the two holes were drilled according to the plan dimensions. |

|

| Next the coupling pin was made up and fits loosely in the hole, but will be fitted with an "R" clip when in service. |  |

| The coupling bar was made up and drilled to size and with a coupling pin also made for the tender the engine and tender were coupled for the first time EVER !!! |  |

| From the time I

started the Tender I have made a mistake and just bolted the

dummy springs into place. They should have been held by 6BA bolt

from the back and not right through. So today I drill our the dummy springs and tapped then 2BA expanded the size of the hole in the tender chassis and refitted the springs. |

|

| The refitting takes

away the nasty bolt hex heads. The plan now will be to shorten the bolts and may be use some filler so that when painted one might not even know of the error originally. |

|

| Continue to next page 24b | |