The Diary of the Building of a 5" gauge Stirling Single |

|

|

|

|

|

|

|

Timing the valves |

|

| 7th November 2017 After watching a YouTube https://youtu.be/Bkq-lMtcv4g several times about setting the valve gear I decided to give it a go, and whilst it looked complex in the video actually is was quite straight forward and worked for me first time. Whilst the wheels did go round on the 6th November the valves needed further attention to their setting to make the running better as it would not go in reverse as initially set. |

|

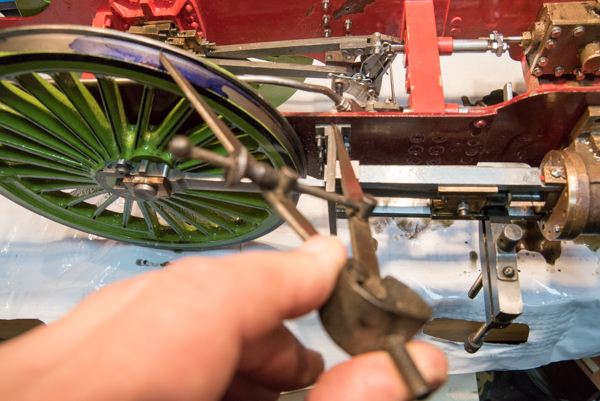

| The stages of the

timing. 1. Take the cover off the steam chest so that the valve is visible. On the Stirling single I set a mirror at 45 degrees so that I can just look down. Put a centre pop in a location accessible from the wheel and I placed that above the bracket which holds the guide bars. 2. place an engineers clamp on the guide bars at a position where the connecting rod is just short of TOP DEAD CENTRE, or FORWARD DEAD CENTRE.

|

|

| 3. I used marking out

fluid so that the marks on the wheel could be easily seen. Make

sure the reverser is set in the forward position as we are to

first set the forward valve position. Made sure the wheel is

turned to have the cross head just touching the clamp. With one

end of the dividers arbitrarily set to a distance, WHICH MUST

REMAIN the same through out the procedure, set in the centre pop

scribe a mark on the wheel. 4. the rotate the wheel until the cross head again touches the clamp but this time the the TDC is below the centre line. |

|

|

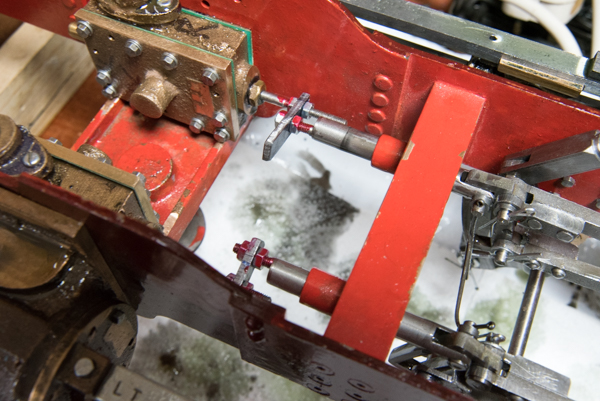

5. Then with a second pair of dividers, so that the original remain set, divide the gaps between the two scribed line until you have located the centre of the two marks. This is the real TDC in the forward gear position. |

|

| 6. Now using the first

set of divided with the unchanged setting move the wheel to the

centre mark and take a look at the location of the valve in the

steam chest. 7. Adjust the forward Eccentric until the valve is right on the line of the port at the front of the cylinder as it would be when it is just about to open. Make sure it is in the correct position and then tighten the locking screws or what ever you are using. |

|

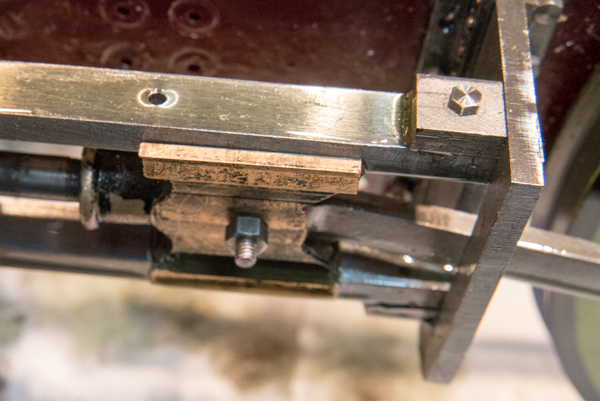

| With all the

adjustments made I decided to apply some nail varnish to set the

nuts in position and so I can tell if they have moved. The same procedure is carried out with the reverser in REVERSE and also for the other side of the loco |

|

|

With a successful run on air forward and backward I decided the drill through the top guide bar to enable lubrication to the top of the cross head. |

|