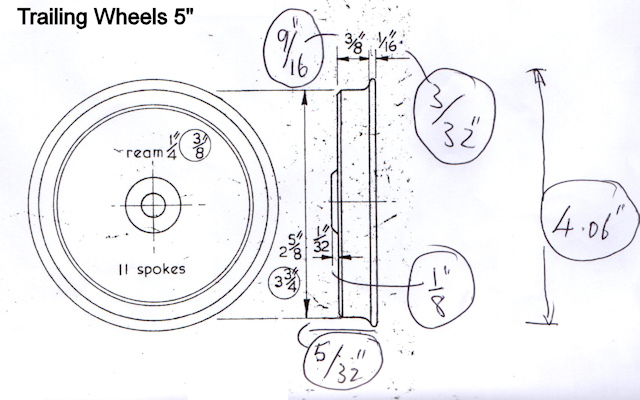

I decided to first to amend the plan of the Trailing Wheels so that I had the correct sizes before I started to take any cuts.

The amended sizes are as shown in hand written notation.

Completed the profiling of the trailing wheels and that only now leaves the fettling of all wheel to remove casting flashes.

There was quite a lot of flash materials from the casting ( you cna see that ins the photo above) which needed to be fettled away so a happy coup[le of hours spent with the file !!

Some repair work to the Dynamometer Car. When tested last Sunday the local speedo decided to fall off. So a new bracket and fixing were devised and completed.

The two holes in the coupling are there to accommodate 5" and 3 1/2" locomotives

I checked the concentricity of my self centering chuck and found it was in error of +/- 2 Thousandth of an inch !!

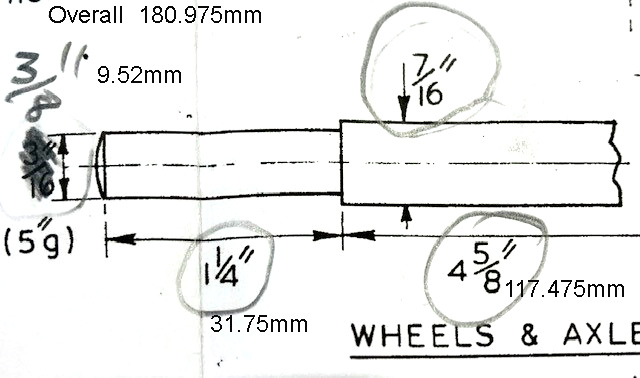

Then I proceeded to turn the tender axles

With the hole in the centre the axle was put in the vice with support beneath to ensure it remained horizontal and the machined piece of bar set down on the axle at the point where I wanted the hole hole.

Drilling then with the same drill as used to drill the hole and some cutting fluid applied it was an easy job to cross drill a hole and meet the existing hole in the axle.

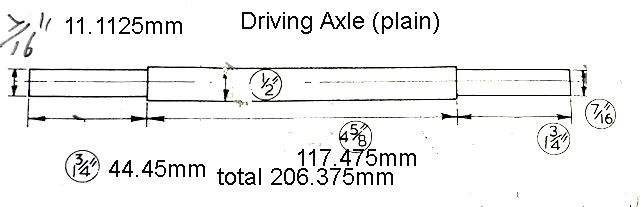

To try to avoid any errors the driving axle was converted to metric.

Completed the machining of the Driving straight axle and remade a tender axle, including the cross drilling as I was not happy with the finish on the Axle Box running surface.

Tidying up some of the excess flashing on the wheel castings more still to do