For the loco the job for today is to mark out two pieces of 3/4"x3/8" steel bar 20 1/4" long and make sue the ends are square.

Also cut the front buffer beam approx 1 1/16" x 1/2" x 7 1/2" and the rear drag bar 1/4" x 3/4" x 7".

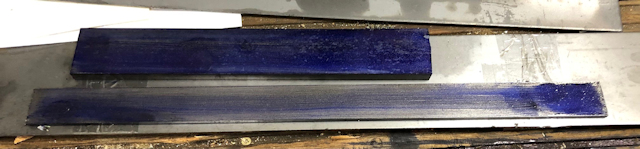

The metal as delivered was covered as usual in an oily finish. This was removed using white spirit on the side to be marked.

Then making out blue was applied by paint bush, which it self was cleaned in white spirit.

Using and engineers rule the parts were measured and marked ready for cutting which was delayed as my injured arm in the fall last week had not recovered enough to carry out the operating.

To be marked out and cut are two 1/8" x 3/4" angle to attach to drag beam and two 3/4"x3/4" blocks to attach the front buffer beam.

I have timber in my workshop which I can use for the formers for making the boiler's flanged plates so I will set to work on that as soon as my band saw is repaired.

Today I turn my attention to the material required for the Tender. The side frames are being Laser cut So I need to determine the front and rear drag beams, The front beam on the plan says it is 1 1/16" x 3/16" and 7" long. The rear beam on the plan is 1 3/4" x 1/2" and 7 1/2" long. The four horns are being laser cut.

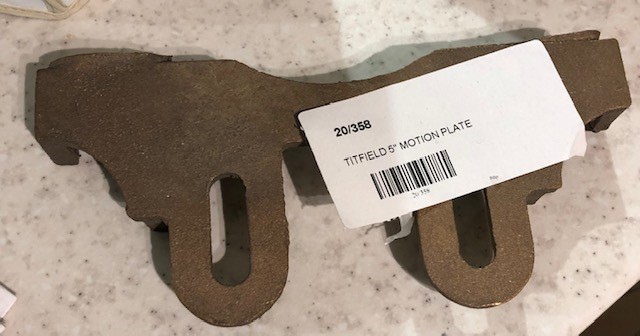

Considering the necessary motion plate for the 5" version so extracted and edited the drawings as shown. The overall width is 6 1/4" inches

Today reading up on making the boiler as on Sunday I will be discussing this with club members.

Also ordered 3 new Metal working band saw blades and they should be delivered next week. My Band saw is the Warco Universal with 64 1/2" blades. I used to make up my own but now prefer to buy them !!

Also a lot of time was spent watching YOU-TUBE videos of

Lion - 5"g Miniature Locomotive Steam Engine Build

Added photos to page 1 of this site. and made up a "viewing saved area" for the YouTube of

Miniature Locomotive Steam Engine Build.

Met up with others at the MMES track and discussed the variation on the flanging of the plate at the front of the fire box and it was agreed it would make a better solution that a but joint.

Silver solder and flux ordered from https://www.cupalloys.co.uk/ so getting prepared for the boiler construction.

I have checked my gas pipe to the flame torch and all is well and I have propane gas.

The Tube plate former was brought to size and a centre location piece made and fitted so nearly ready for the flanging of the tube plate !!

307 Tender horns

308 Loco front horns

309 Loco middle Horns

310 Loco trailing horns

1075 inside frames

1076 Motion plate as I forgot I had a casting !!!

18263 Sole plate

18205 Side plate

18266 Rear plate

The tube plate was marked out by first linking the corners and then centre popping and finally drawing a circle to the max size. The disc corners were then cut off in the band saw and then was sanded round and the centre hole drilled the size of the post on the former.

As it was raining the disc could not be annealed so will wait for a better day.

Today the flanging of the front tube plate was commenced and after 2 hours of annealing and hammering and more annealing and hammering several time this is the result so far.

It does fit the tube nicely but a little more work to make it fit fully in is required but enough hammering for today and also the former needs to dry out as I did not dry off the plate between hammering !! This resulted in it being very difficult to remove the plate !!

Created a 1:1 scale drawing of the Front Firebox Shell as the existing drawing was not to scale!!

Cut a suitable piece of MDF to act as a back piece but found that I did not have a pencil compasses so bought that for delivery tomorrow when I can continue with the preparation.

Purchased a new Jig saw to be able to cut the copper and also the MDF.

A trip to MMES to see my mentors. They were pleased with my flanging and said that it could be finished off in the lathe held in a three jaw chuck and a revolving centre to stop it coming out.

With very gentle cuts the turning was completed and the the sharp inside edge de-burred and out edge had it sharp edge filed off.