|

29th April

continued

The four

corners were linked part drilled and bolted part glued.. While the super

glue set the corners were held in place by light weight clamps.

Checks were made that the corners were at right angles.

Sorry about the reflection but the surface plate is a piece of

glass.

When setting the cylinders in place the front pair of angle face

forwards !!!

|

|

30th April

2023

The last

angles are stuck in place to secure eventually the cylinder block

to frames.

|

|

So the

holes of the previous glued angle parts is done and the photo

shows the final glueing up using the wooden block to centre at the

rear. before the last gluing of the frames followed by drilling. I

guess they will be unbolted many times before the loco is in a

finished state.

|

|

1st May 2023

All the angle pieces now drill ed and fitted temporarily as they

will need to come off again and set the right way up..

|

|

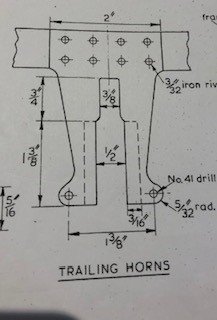

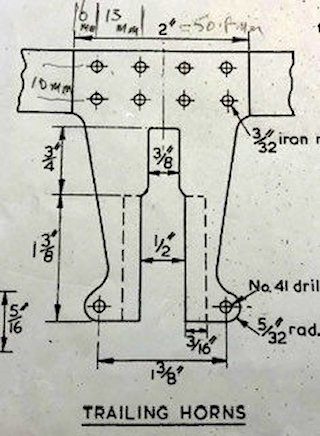

So

the next parts to consider are the horn plates for the loco. I had

these laser cut months ago. They are three different profiles from

left to right, Front Centre, Rear. the plans show the positions

based up on the centre line of the horn blocks. They will be

covered in marking out blue and the the fixing points marked and

drill as a pair in each case. The location of each will be marked

and drilling on the side pieces of the chassis which will also be

bolted together so that they are a marched pair.

So a lot to think about and prepare.

|

|

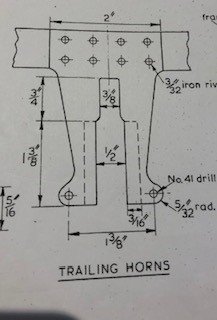

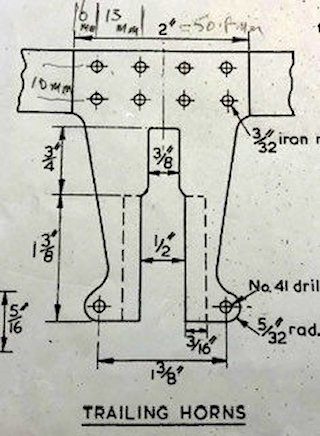

This is

from the plan and shows that rivets are required !!!! I must check

I have plenty in stock !!

|

|

2nd May

2023

The horns

were glued together in preparation for being drilled.

|

|

Marking out

fluid applied so marking out can be done soon.

|

|

3rd May 2023

Measuring the

position for the horns was not easy as I had to add inches and

fraction of inches and then subtract half the width of the horns.

Eventually is was achieved. The measurements were double checked

and then treble checked as I did not want to make a mistake.

|

|

I need to

establish dimension which are not initially readily seen on the

plans. The plan indicates that the part which slides in the horn

and its added block is 1/2" wide which with the horn itself 1/8"

indicates that the block must have a thickness of 3/8"

|

|

The spacing

of the rivets is 13mm horizontally and 10mm vertically distance

from end is approx 6mmm!!

Metal and rivets not ordered from Maidstone Model Engineering.

|

|

5th May

2023

Made up the needed adaptor from M12 to 3/8"UNC for the new

mill cutter so the the shaft that holds it in place can join with

it. A second one was made for the drill holder

|

|

8th May 2023

After a

break to watch King Charles III Coronation and Coronation Concert

I decided to finish drilling all the rivet holes in the axle

box horns.

|

|

|

|

|

|

|

|