Following my second cataract operation a couple of days ago no engineering for the time being.

However I can look at plans and see how to proceed.

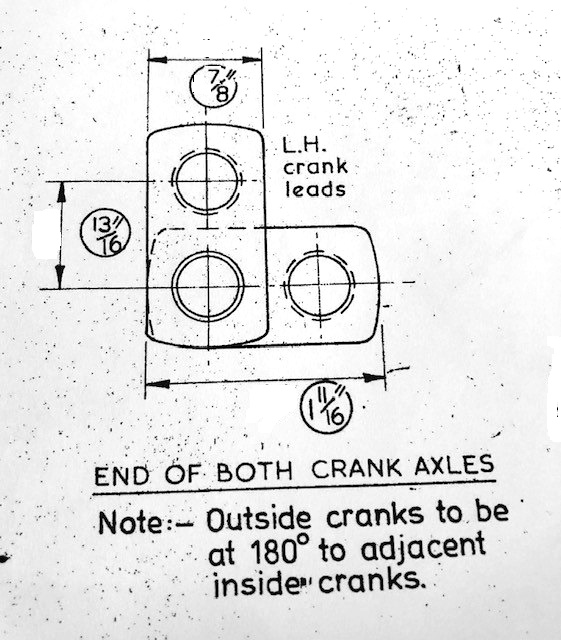

Looking at the plan of the cranks I noted an error in one of the sizes so corrected that to 7/8" and deleted all the references to the 3 1/2" gauge model.

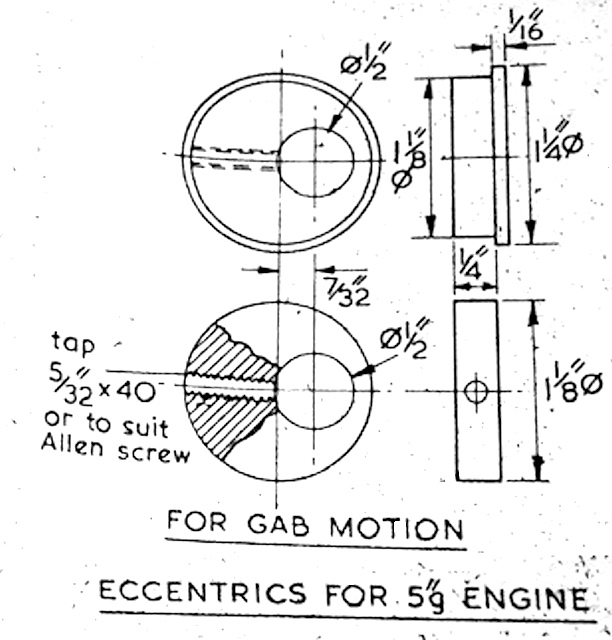

Which gear to choose. I have been told by a friend who has built the Lion that the Gab gear is as on the original - see opposite.

The disgram shows an extraction ofrom the plans and indicated that the eccentrics whilst they are identical in size 1 1/8" diameter and 1/4" thick one of them has an additional flange of 1/16" at diameter of 1 1/4".

The hole off centre by 7/32" is 1/2"

A pair of these is needed so to start with I need to cut of stock bar two pieces say 3/4" thick to make it easy to hold and machine to the 1 1/8" size and to depth of 1/4" before turning round and machine to the Outside diameter and bringing to thickness of the flange then cut two pieces say 5/8" and machine without flange !!.

Then I will assess the allen screws I have and see what thread needs to be cut etc

After second eye operation back on engineering

The banks for the eccentrics were cut from a bar. I did cut 4 blanks but machined one before taking photo.

Two more eccentrics made except for the offset hole

Final eccentric machined and all marked for the offset which will be check measured before completing the drill and reaming

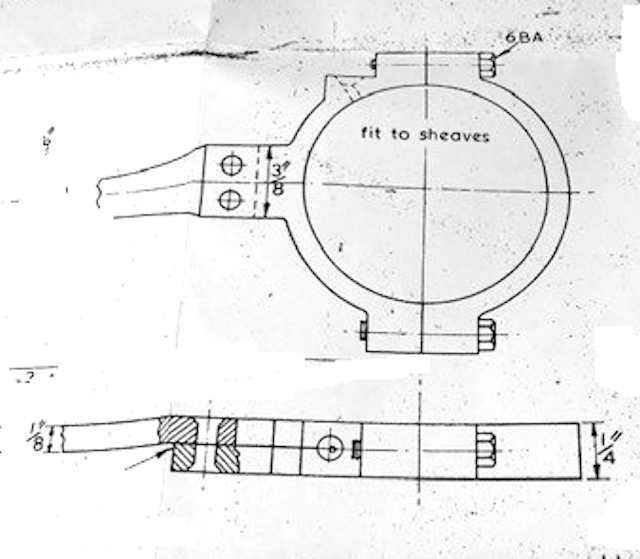

Considering the eccentric straps and decided the the eccentrics should be finished first and the straps need to be made to fit the eccentrics !

Overhauled the suds pump of the lathe coolant system which was completed blocked and seized up !!.

A new piece of gauze was cut to cover the whole of the underside of the cover to replace a small gauze set in a rubber ring as original which would not remain in place..

Tested on plain water and all worked well

Grease was applied to the three fixing holes

But when put back on the lathe it would not pump water up to the out let. So the filter was taken off a sealant applied around the joint surface and all bolted up and left over night.

The test the next day was fine ...

Sorry for the delay in progress but I lost one of the eccentrics at the back of a cupboard support which I only found this morning. Had it not been found I would have had to have given it up for lost and make another !!!

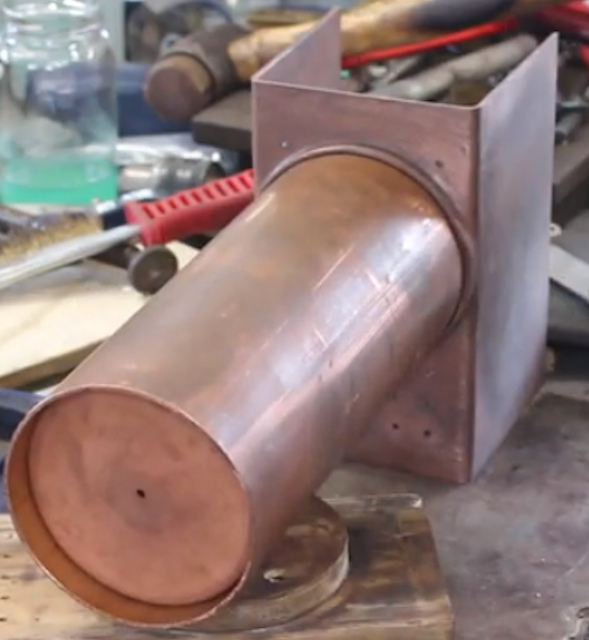

Considering the boiler and watched this video https://www.youtube.com/watch?v=xmigipwkO0o

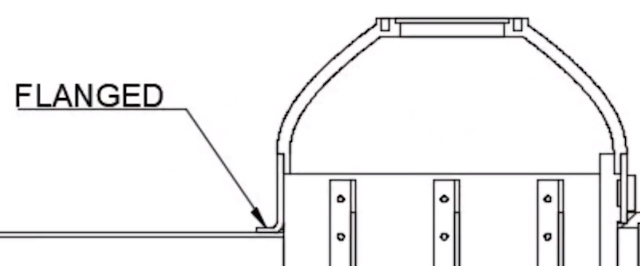

The photo was extracted from video

the video shows the former to enable to side to be flanged

The video is very good so do watch it !!!

After cataract operations I am back to engineering ..

https://youtu.be/XbMiM0YT5sw

the photo is an extract from video

I have double checked and the straps cost about £25 so let get going on the machining of the straps already purchased !!!