| 13th

October 2010

The idea was passed to me by a

fellow model engineer that it might be

worth trying an electronic igniter which

run on a 1.5V battery. The packet says

"Quick multi-spark and was purchased

from eBay

(suggested search Electronic Igniter and

I saw LIGHTER FOR GAS COOKER -

ELECTRONIC IGNITER & BATTERY

)..

When

the battery was inserted the spark cam as

soon as the button was pressed sparking

between the wire electrode and the black

metal case.

|

|

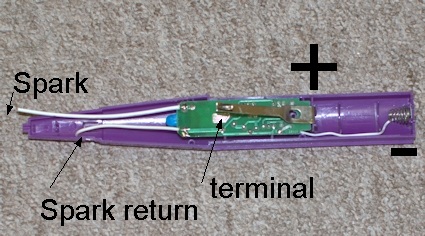

| To open

up this particular igniter there is a single

screw access from the rear of the case using

a very small cross head screw driver.

When

open this is what you see. It is very

important to keep a check on which wire

goes where else failure is inevitable as

electronic circuits do not work when

powered back to front ie - and + reversed.

The

push switch is held up by a piece of

spring steel that may well be used in the

project in another section.

When

the spring is pressed it joins the +

terminal of the battery to a little pad

marked "terminal".

It is

important to note which is the spark

return and which is the spark. The spark

return is common with the - terminal and

would be attached to the chassis of the

motor.

That

going to the spark will be the HT going to

the spark plug.

|

|

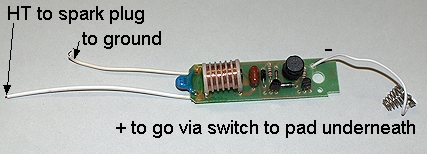

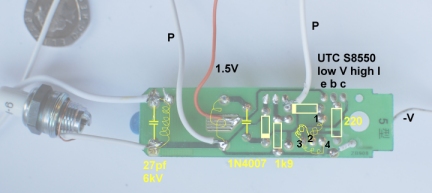

| This is

the PCB from inside the igniter - removed by

releasing a small screw adjacent to the

spring clip.. The various wires have been

identified but note they refer only to this

igniter others may be different.

It is

very important to know which is the HT and

which is the GROUND mixing these up will

almost certainly ruin the igniter or

worse.

The

next stage will be to set up the igniter

with a spark plug and prove or otherwise

that a spark can be generated.

|

|

| 14th

October 2010

The

whole unit was taken to an friend who is

up on electronics and he is to run some

tests to see what is the potential to use

the unit to create the spark.

17th

October 2010

His

tests have resulted in a spark across the

spark plug so it does look like this idea

might well work!!

|

|

| 20th

October 2010

Further

tests have shown that the automatic

repeating spark can be stopped and the

spark created on demand by removal of two

components.

Due

to the complexity of the electronics and

the very high voltages generated ( likely

to be in excess of 10,000V ) further

experimentation must be left to those who

under stand what they are doing.

Suffice

to say that the use of this item does look

exceedingly promising.

|

|

| 26th

October 2010

The

spark plug used is a :-

- Traditional

Spark Plug NGK Spark Plug CM-6 5812

- Gap

0.016" (0.4mm)

- Thread

Size M10x1mm

- Reach

8.6mm (.339")

- Hex

Size 9/16" (14.3mm)

- Gasket

Seat

- Non-Resistor

- Solid

Terminal Nut

- Heat

Range 6

|

Better

picture soon !!

|

16th

October 2017

I have returned to the web diary of my build

as I have changed the ignition system.

A friend of mine who has worked on cars and

earlier on motor cycles offered to sort out

the ignition system and help me to

understand what is required.

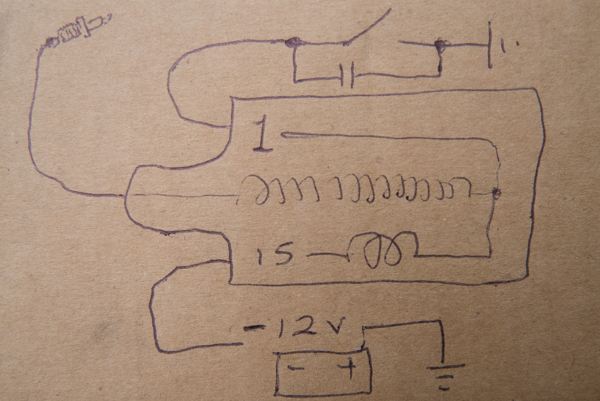

The drawing may look like it is on the back

of a "fag" packet but it is actually on the

box in which the coil and capacitor were

delivered to me.

Note that the positive connection of the

battery goes to the chassis as it would have

done on the motor cycle.

The following was suggested :-

12V Ignition Coil With Bracket Ideal for

Classic BSA-Triumph-Norton-Motorcycle and a

Lucas-Condenser-As-fitted-to-BSA-C11G-1954-5.

These were purchased from Ebay. |

|

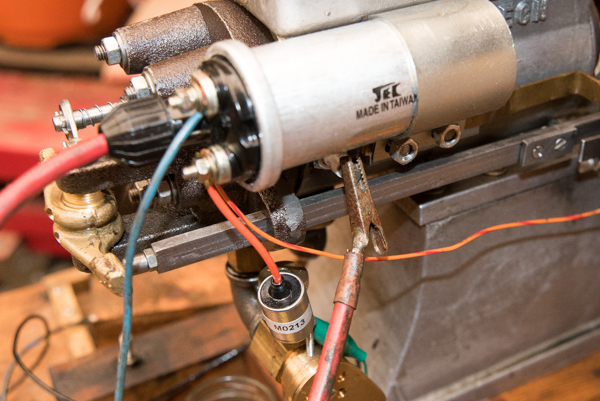

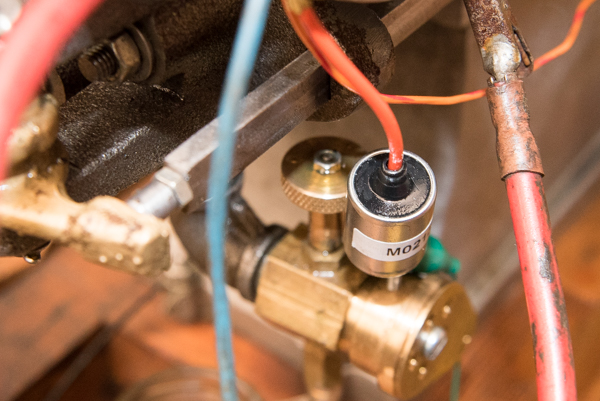

What

can only be called a "lash up" was done to

prove that it is a viable solution.

It is viable and a great spark is obtained

even with a very short charging of the coil

as the current arrangement allows.

The "points" have a small run where the

contact touched before the breaking of the

contact takes place causing the spark.

|

|

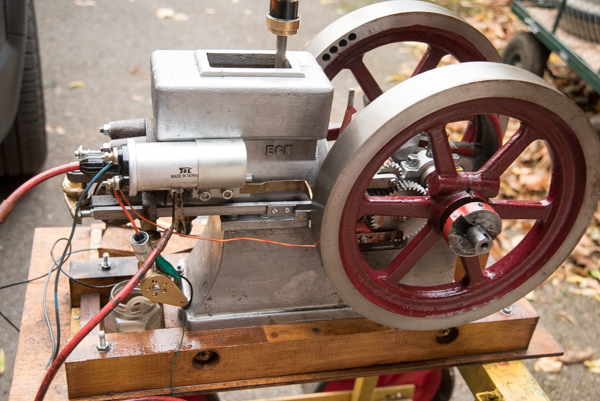

Having

cranked the flywheel over many many times

and sort of had a few firing a better way to

turn over the engine was needed. Whilst I

have no picture of that it was found that be

depressing the inlet valve the flywheels

would turn over and there was no

compression.

An other lash up of an electric drill and a

buffing head was put to goo use. By applying

the buffing head to the flywheel and using

the electric drill and with the inlet valve

depressed the speed of the flywheel far

exceeded that of the crank and soon the

engine was spluttering to life and

adjustment could be made to mixture and

amount of air with the druill still cranking

the engine.

It was found that the mixture needed to be

set at one half a turn from fully closed and

after the fuel had been sucked up the tube

the choke cracked open. |

|

The

engine ran until the fuel ran out, as we

were only using a small pot of fuel but the

water did boil in the cooling head.

It has been decided that the engine would

benefit from being able to adjust the timing

point whilst it is running in addition to

the fuel mixture and air ratios.

Work on the engine is therefore ongoing ...

|

|