26th

October 2020 continued.

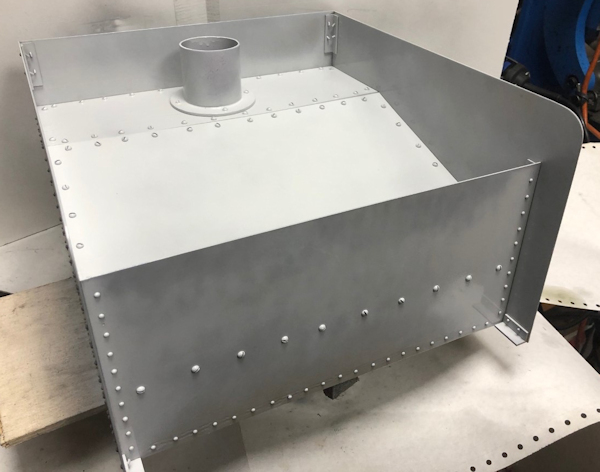

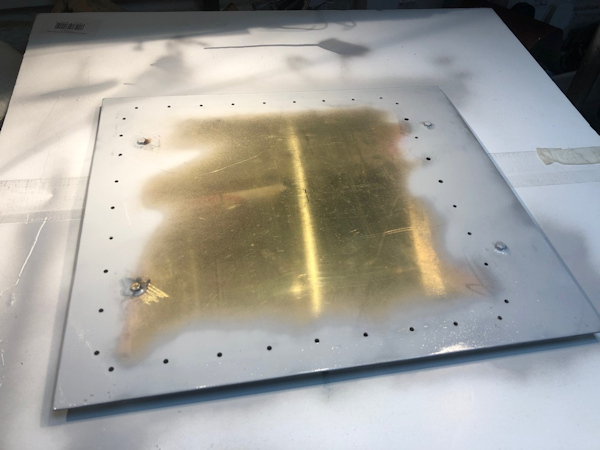

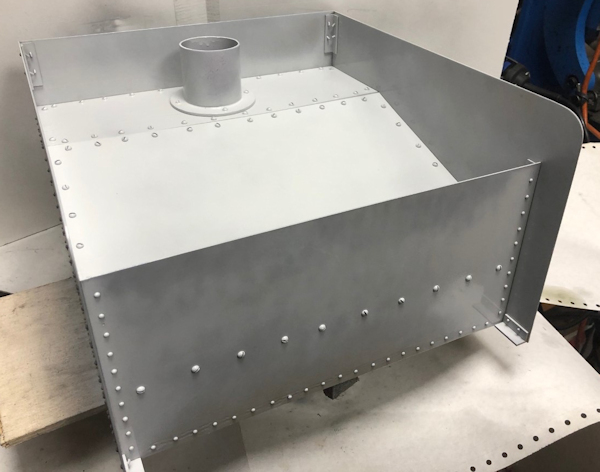

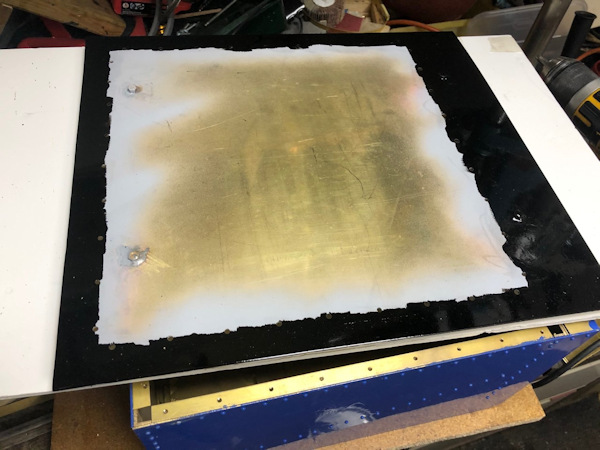

A

make shift spray booth with a turn table and wooden base

the etch primer was applied.

This only took a few minutes and the turn table made the

application so much easier than having to move the

tender round.

The Etch Primer now needs at least 24 hours to properly

cure as the makers instructions states "Never ever apply

two coats of paint on the same day unless there are

clear instructions to do so on the label or technical

data sheet" well there are no such instructions so I

wait until tomorrow.

.

|

|

27th

October 2020

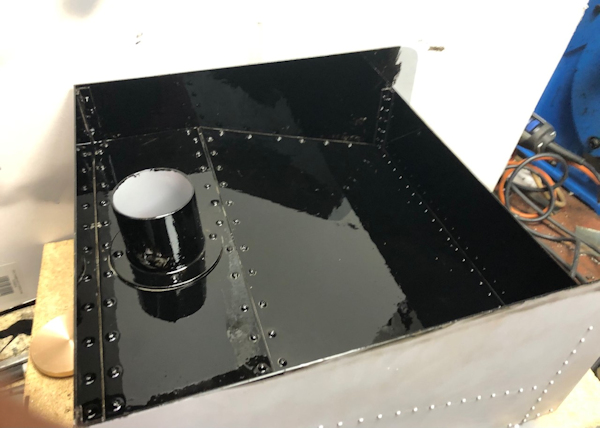

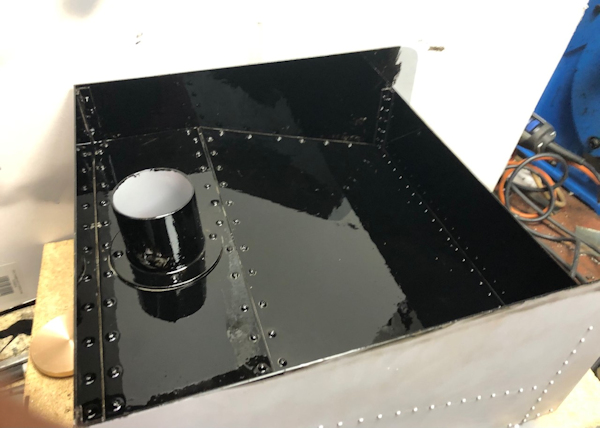

With the etch well cured it was time for some black

paint in the coal bunker !!

|

|

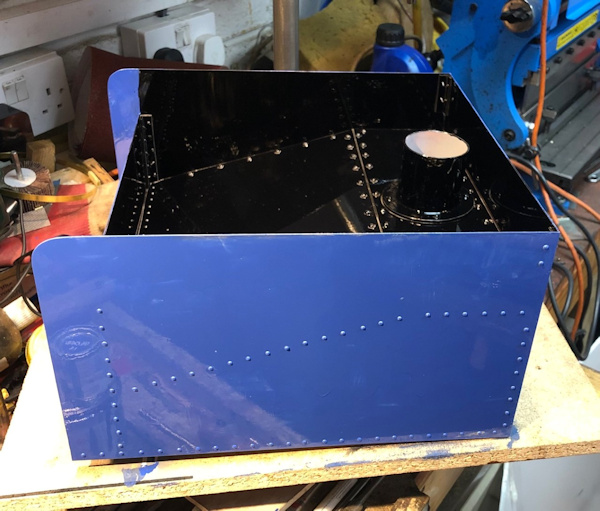

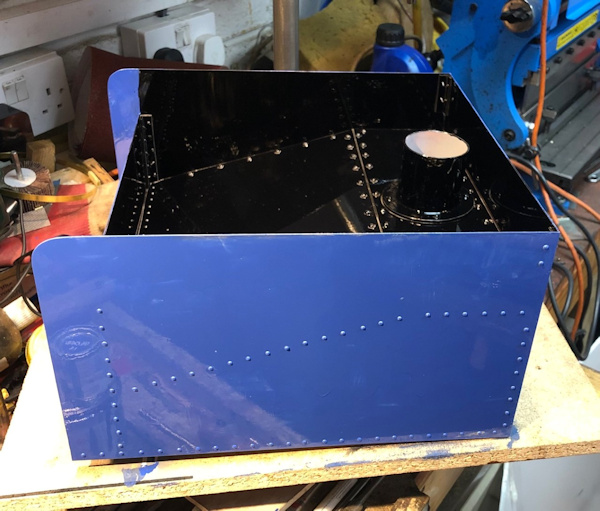

Then later in

the afternoon I painted the first coat of blue paint

similar to that on the loco.

|

|

28 October

2020

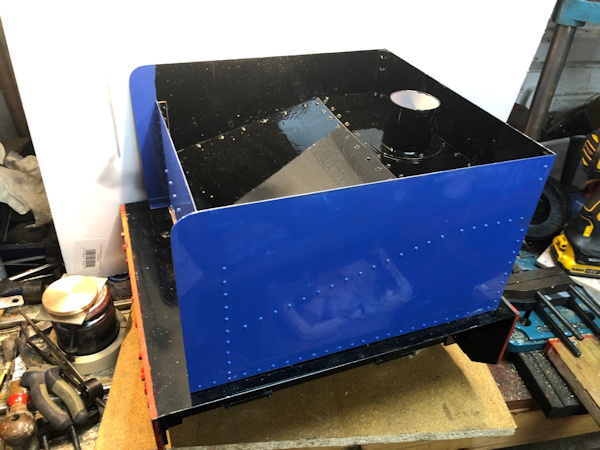

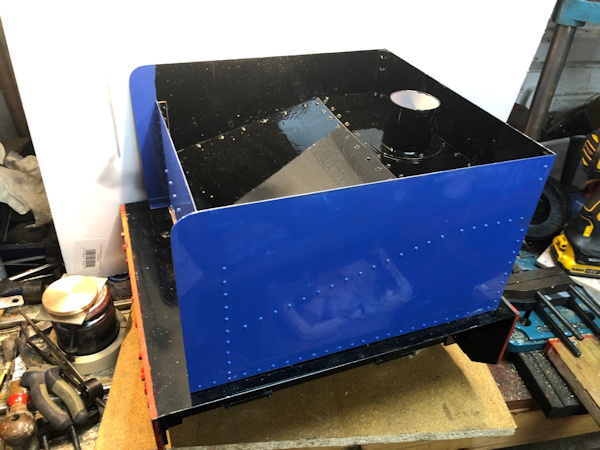

All together for a trial full fit but there is still the

second coat of paint to go on and a few other small

items to complete, such as using counter sink bolts as I

did not mark where the frames of the tender would sit

and by chance four of the bolts are exactly where the

frames need to sit but I have had to order counter sunk

bolts !!.

A track test once the coupling bars are fitted

will be next up.

|

|

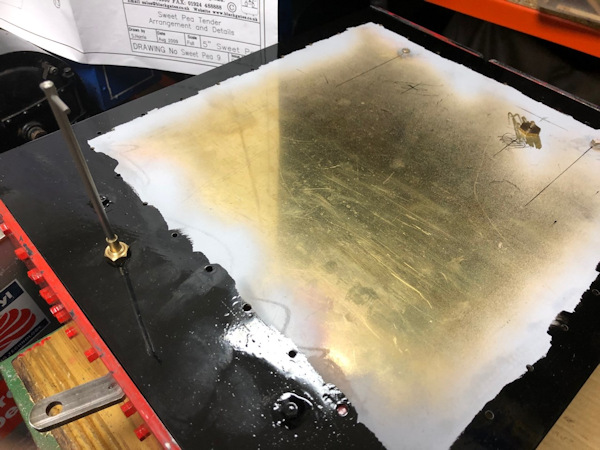

29th

October 2020

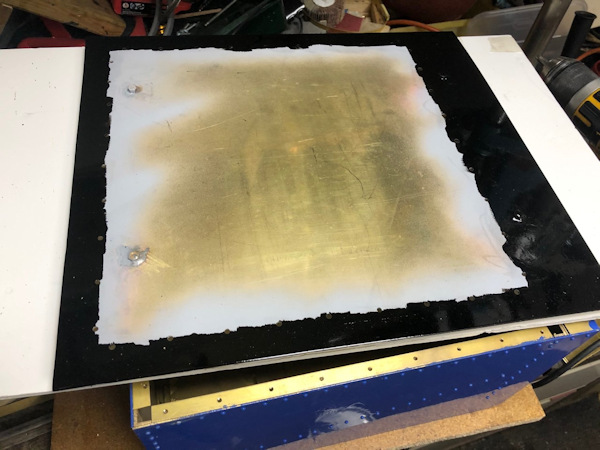

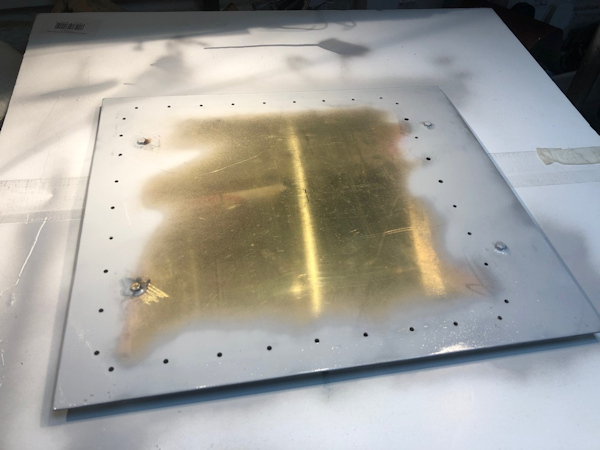

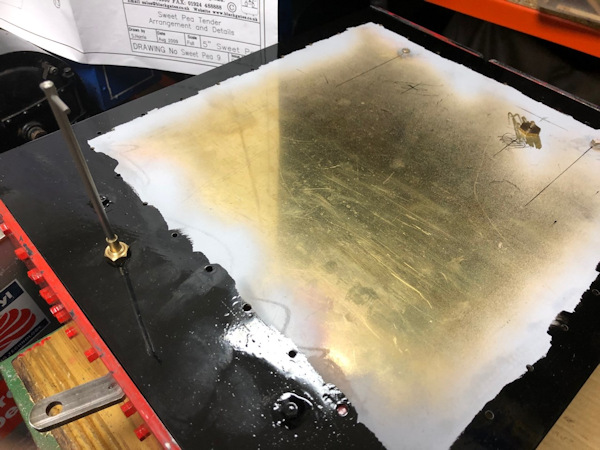

When something goes wrong I find it better to start over

again so the etch primer and black paint were sand

blasted off and new Etch Primer sprayed on. The problem

was that at the front edge I had not sprayed

enough etch primer as I had masked up incorrectly

so the black paint also fell short. It will be fine this

time as also all the holes have been drilled out as

clearance holes for the bolts and four holes counter

sunk.

No rush to paint as the counter sunk bolts have not

arrived !!

Also I have to drill and fit the coupling bars.

|

|

30th

October 2020

So the new coat of Black Paint was applied early morning

and this was dry by late afternoon.

|

|

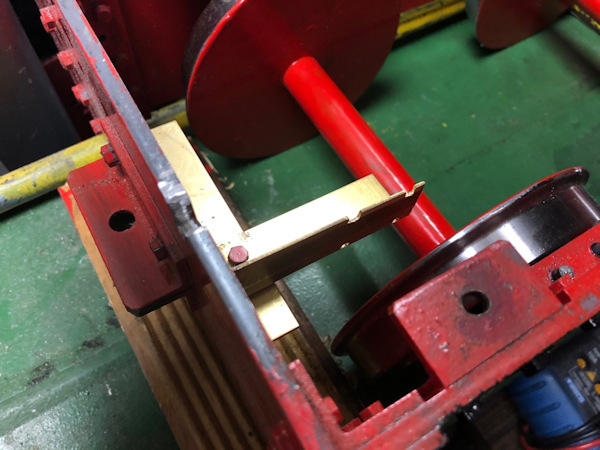

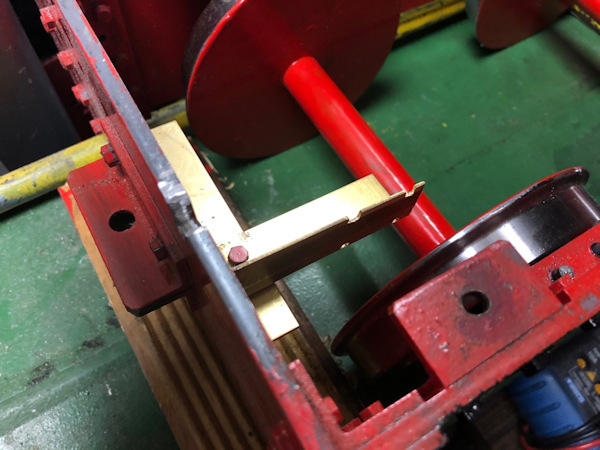

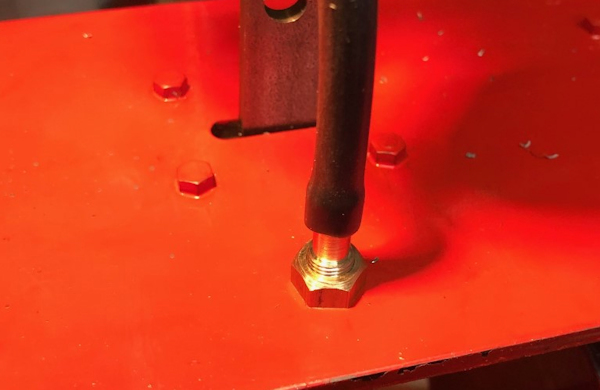

I decided to

put the towing hook on the out side and this then

allowed me to put a bracket for the Speedo on the

inside. The bracket is made of brass so that there is no

magnetic interference to the sensor as the magnet

attached to the wheel rotates past.

I also cut a grove in the buffer beam to allow the wire

link from the sensor to the display to pass through.

|

|

1st

November 2020

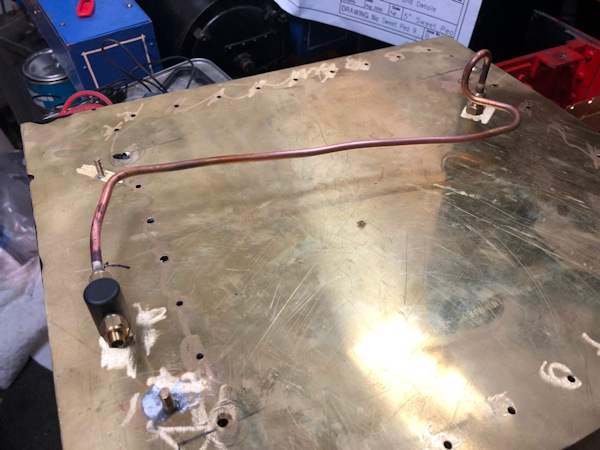

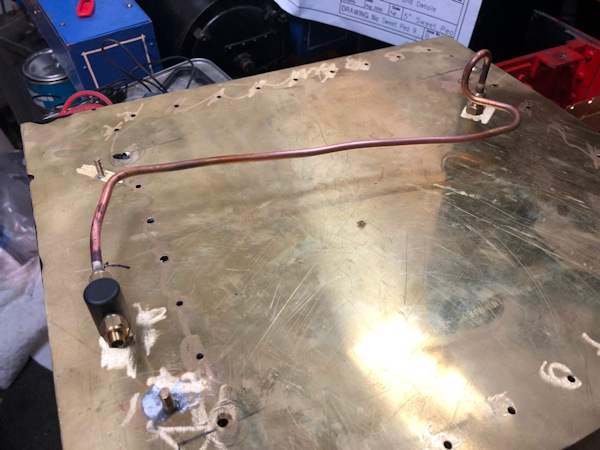

I had to work out where the pipe run could go to avoid

the wheels and side frames. The positions wewre marked

and then drilled 5/16" for the fittings.

|

|

The

3/16" pipe had to be bent to fit. Thanks to a hand tool

given to me by a friend I was able to make suitable nice

bends and with a little adjustment it fitted !!

|

|

2nd

November 2020

Just a single piece of pipe work fitted today to check

that when I have drill the hole in the buffer that the

bends made all fit.

I have to purchase a 36" piece of 1" solid Steel to

extend my drill to make the drilling of the tender

easier, of course there is no way I can use that to

drill the loco so a hand drill for that will have to

suffice.

Still awaiting the delivery of the counter sunk bolts !!

|

|

3rd

November 2020

I obtained the 36" of round steel bar but had to machine

the end to fit the base of the old pillar drill. The bar

was too long for the laths and would not go through the

chuck so I make a wooden steady.

This allowed me to machine as needed the diameter by the

chuck and what I could not machine I cut off in the band

saw.

|

|

The new pillar

is installed and drill ready for use.

|

|

4th November

2020

The new pillar worked very well and the hole in the

front buffer beam was drilled with out a problem.

|

|

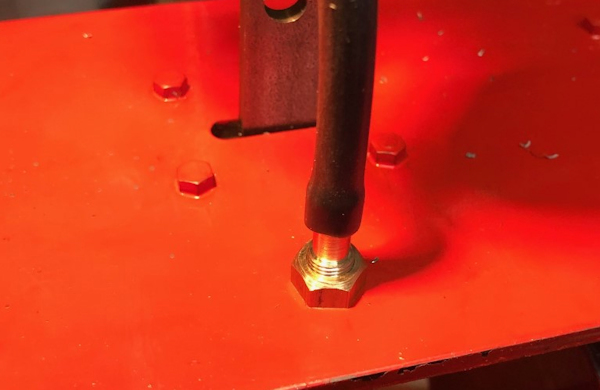

The fitting to

take water from tank on tender to loco was made and

fitted.

I have still to couple up the fitting inside the frames

to the tank fitting.

|

|

12th

November 2020

The "speedo sensor" bracket was fabricated from bending

pieces of scrape brass sheet and then bolting together.

The some soft solder was ured to maintain the position

but also to enable to to be changed should that be

needed. The necessary holes and recess were drilled and

filed into place.

I 3D printed a cover for the magnet to give a larger

surface area to stick it to the wheel.

|

|

8th July

2024

|

The speedo has

never been fitted !!!

|