21st October

2020

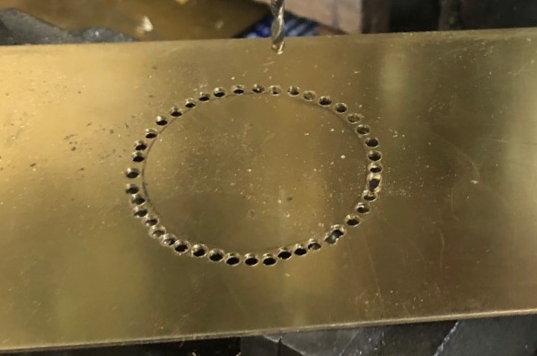

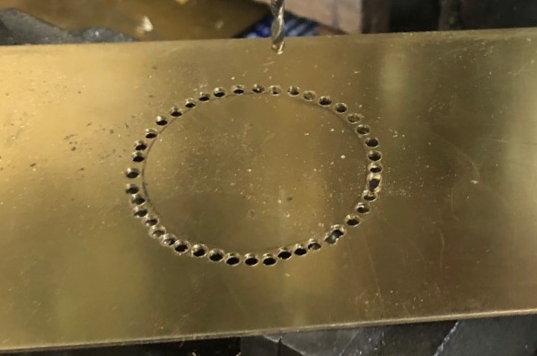

The filler hole was marked out and chain drilled.

|

|

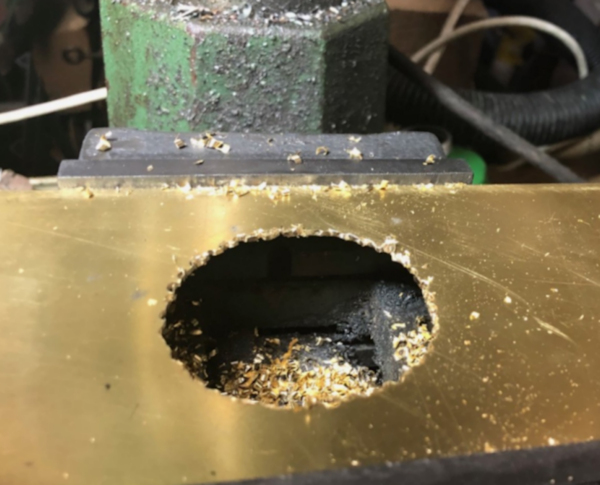

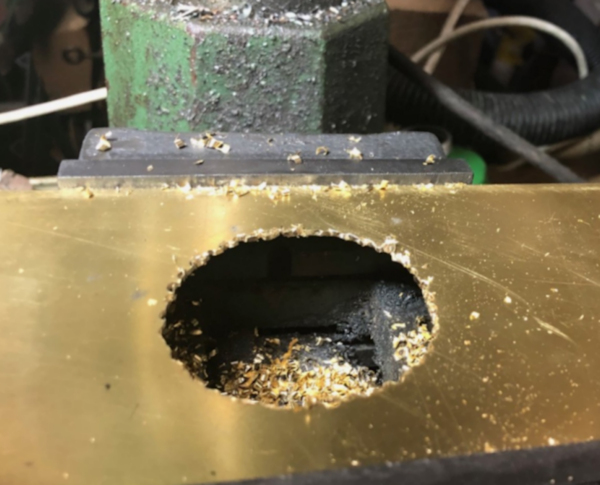

The centre was

then milled out.

|

|

This left a

ragged hole

|

|

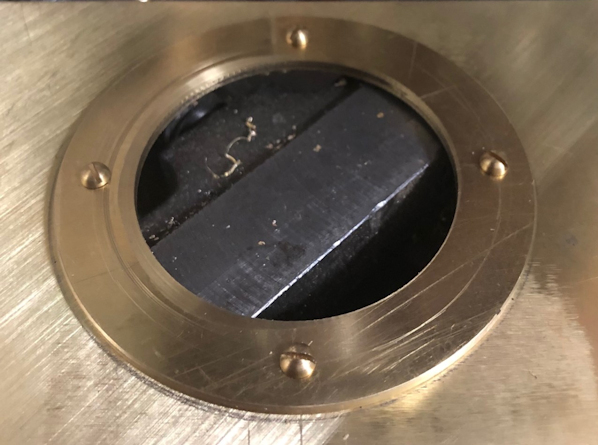

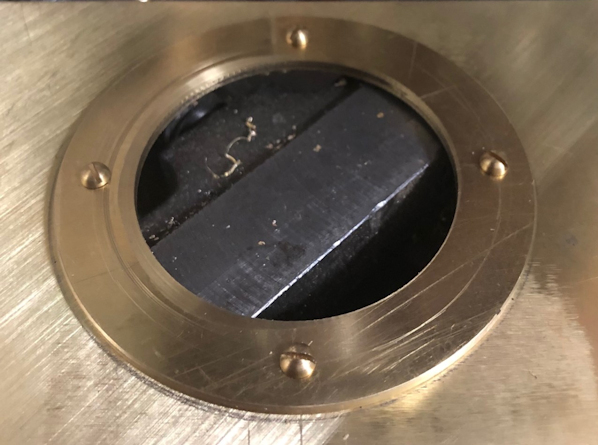

The hole was

cleaned up using a Flapper Wheel

|

|

Having used my

centre finder and marked the two hole location I needed

to mark the next two holes at right angle to the first

two.

So I used a pair of dividers and where the lines crossed

was the centre point between the other two marks. This

was repeated for the other side. |

|

The filler

ring was then fitted before it is to be silver soldered

to the filler tube.

|

|

The base and

the filler barrel were silver soldered together.

|

|

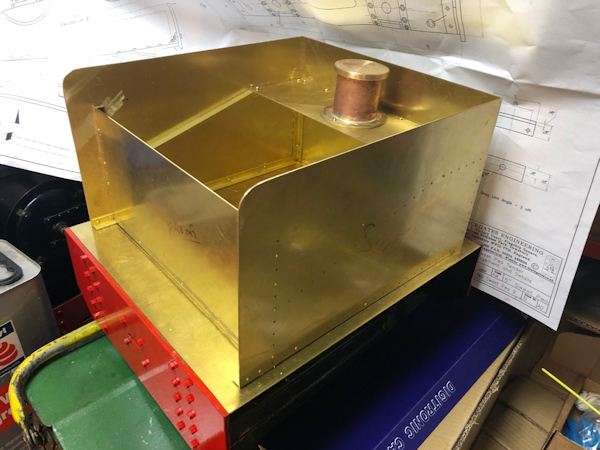

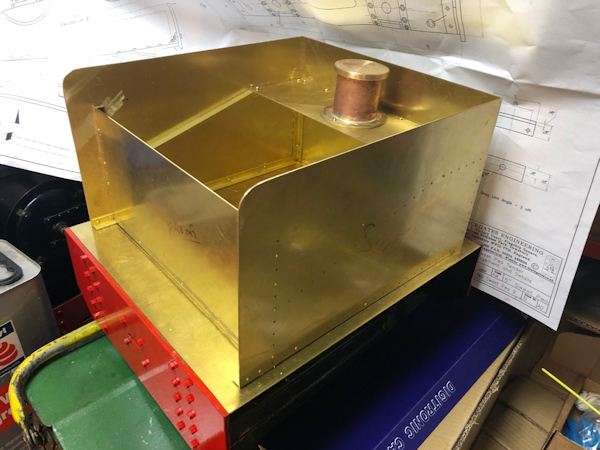

The filler

part had the angle attached so I thought I would hold it

in place to see how the size looked. I am pleased with

my decisions !!!

|

|

22th

October 2020

1/16" rivets drilled and installed a total of 38 so far

|

|

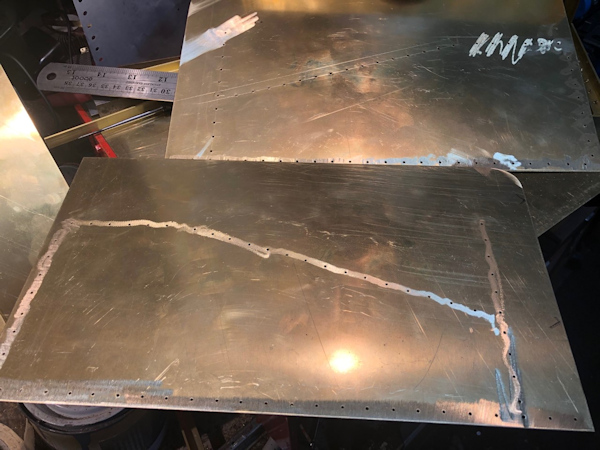

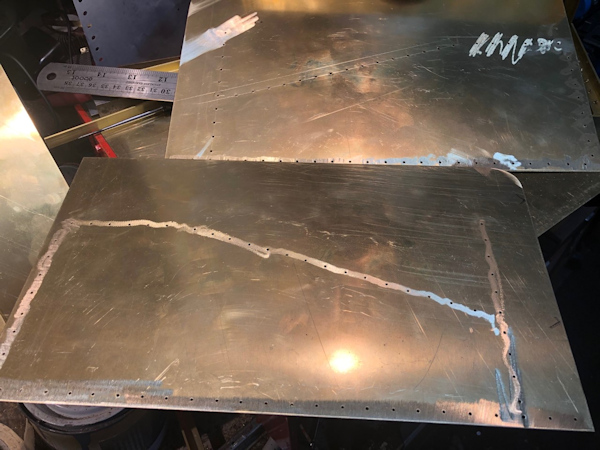

A side piece

was selected and all the necessary rivet holes marked

out - a total of 63 !!

The the 63 holes were drill 1/16" and then the second

side was fixed by machine clamp and carefully 5 rivet

holes drilled and then the two plate riveted together

and the remaining holes drilled.

A total of nearly 200 holes were drilled today

All the drilling was then cleaned up ready for the abgle

to be fixed in another session in the workshop.

Total time today 6 hours of and three broken 1/16"

drill which were not of the best quality!!

|

y ...

|

23rd

October 2020

Holding piece in place ready to drill for the Rivets

|

|

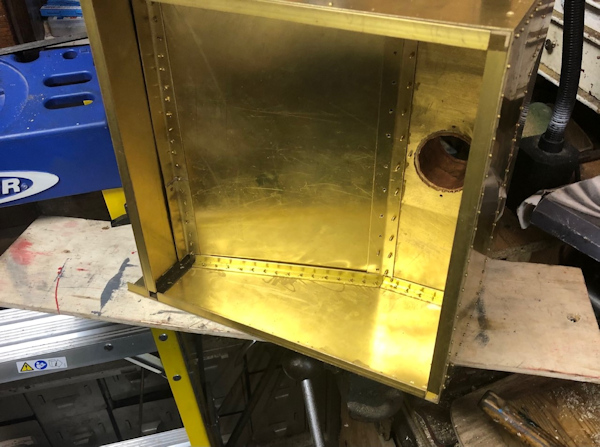

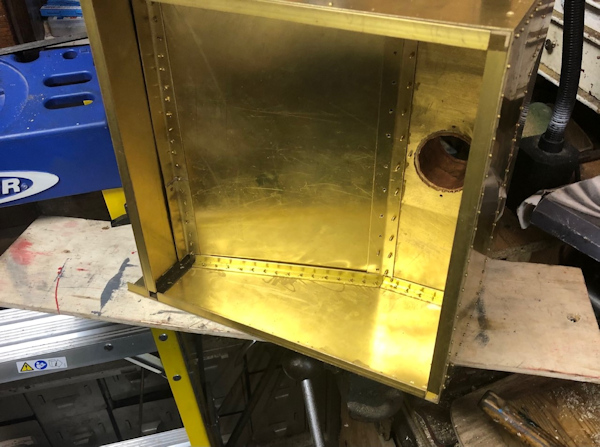

So after a

long session today this is as far as I have reached.

|

|

24th

October 2020

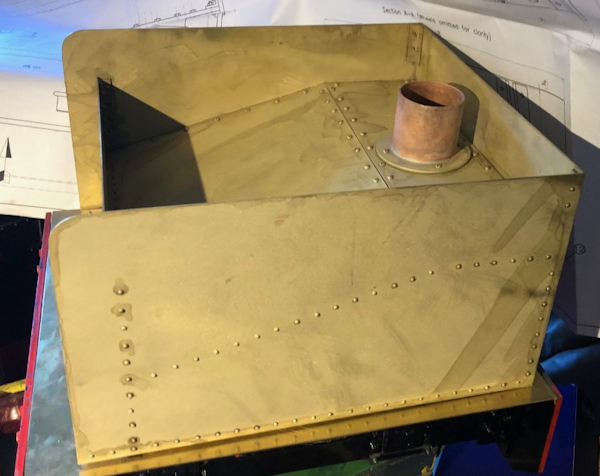

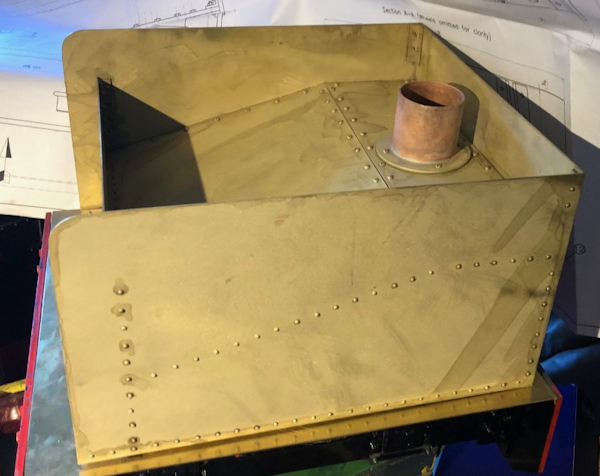

A lot of drilling for 1/16" rivets and then I decided to

sort out the sloping part.

The sheet brass was measured and cut in the 3 in 1

machine and then slight adjustment was needed at the

front end to go round the existing angle. This was

achieved with my Dremel and a metal cutting blade.

Satisfied with the fit I then made up an angle piece

from and off cur using the 3 in 1 machine to form the

angle. I did make a few trial bends to ensure that as I

only had one piece of brass that it would be fine.

The existing part was first drilled with the drill for

the tapping of the lower part, then

the two piece were clamped together using spacers and

machine clamps and the holes for tapping 6BA were

drilled into the lower part.

The upper part was then drill for clearance of the 6BA.

Using a tapper tap 6BA in my hand drill the lower holes

were threaded and then the 6BA round headed bolts

fitted.

A rather neat way of using up the cut off brass.

|

|

A similar

exercise was carried out the make a less than 90 degree

angle piece for the bottom edge. However there was only

short pieces of scrap so two were silver soldered

together cut to length and then bent to the angle

required.

This piece was then attached to the front edge of the

slope by more 1/16" rivets.

This sloping part has to be made water tight as

eventually I wish to carry extra water for the

injector.

|

|

A few more

holes drilled and tapped this evening but I need an

adaptor to gain access to a tight corner so used a

Meccano Coupling.

|

|

25th

October 2020

The first job achieve was to make and extension for the

Tapping drill for 6BA and also an extension for the 6BA

taper tap as they could not reach deep into the tender.

A hole was drilled using the tapping drill and then the

hole and drill were cleaned and then fixed with Loctite

603. Similarly for the tap.

To assist with the riveting I devised this support so

that the tender rivet was on top of the dolly and then I

could balance the tender more securely than without the

stand.Still many more rivets to finish off!!

|

|

With all bar a

few remaining 6BA bolts to drill and tap along the front

face of the tender I decided to see how coal the tender

would carry. I filled a bag with coal and was surprised

to find that it weighed 2lbs 8ozs which as you can see

will easily be carried by the tender.

|

|

26th

October 2020

A start made on the sand blasting so that the etch

primer will have a good key. You should be able to see

the areas sand blasted top left and un-blasted bottom

right.

|

|

The upper part

of the tender is now fully sand blasted and ready for a

coat of etch primer after a time has elapsed to allow

any remaining cleaner to evaporate.

|

|