17th

October 2020

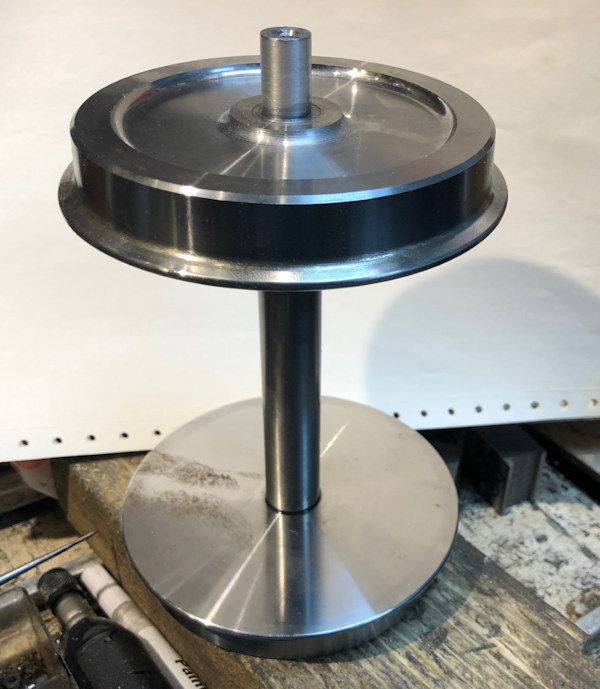

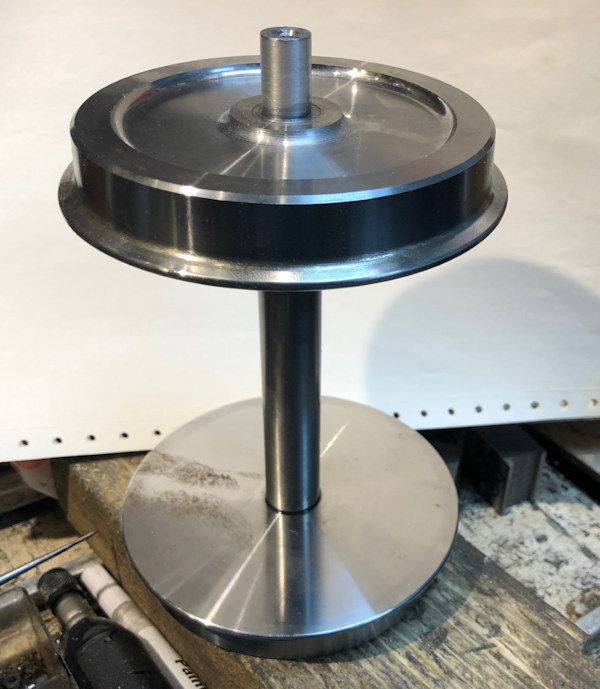

The axle blank was measured and then brought to length

in the lathe.

Then the part to hold the wheel was

machined followed by the part which will rest in the

axle box and lastly the end was centre drilled

|

|

The axle was

then de-greased where the wheel will sit, Locktite 603

applied to axle and wheel and the wheel put on and

turned back and forth a little to spread the 603 and

stood in the recessed piece of timber. Then similarly

the other end was prepared and the wheel put into place.

The Locktite is now left to cure.

|

|

The spring

retained had several simple turning operation to do and

make 8 of them all the same ..

|

|

18th October

2020

Turning a square piece of Brass round the corners you

can just make out !!

|

|

Ready to

remove when lathe stops and then more progress can be

made to the plate work in brass to attach to the

Chassis.

|

|

now the wheels

are painted.

|

|

19th

October 2020

With all paint dry I was able to assemble the various

parts. I had to drill the spring support on size bigger

and then every thing fitted ok!!

|

|

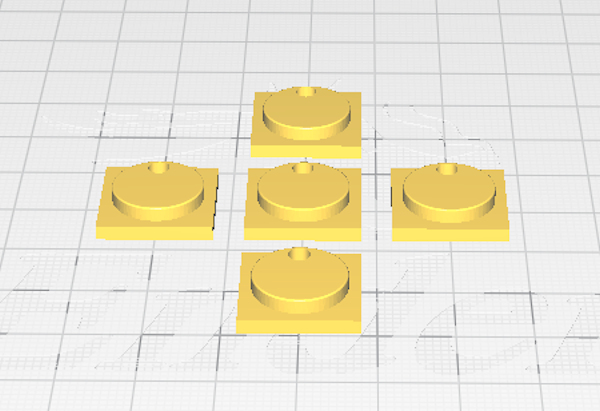

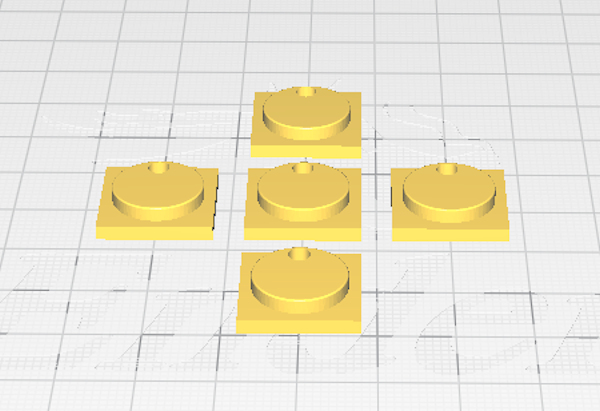

3D printing

the endcaps for the axle boxes 5 printed in case I ruin

one !!

That have a hole in the cap to facilitate oiling.

|

|

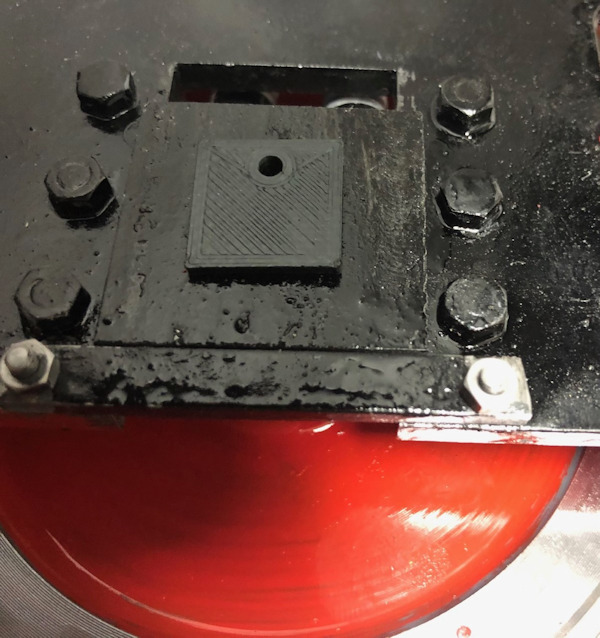

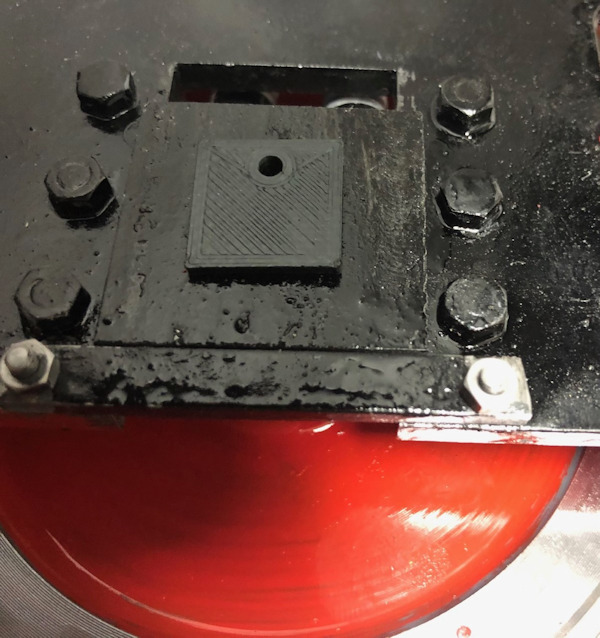

The 3D printed

axle cover fitted a treat with just a gentle knock on

with a hammer.

The hole is to facilitate oiling

|

|

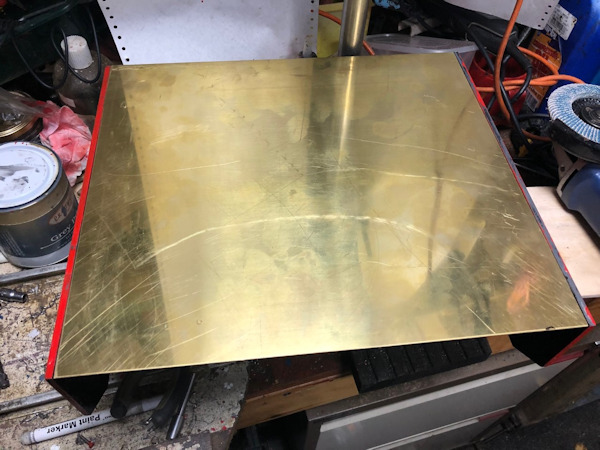

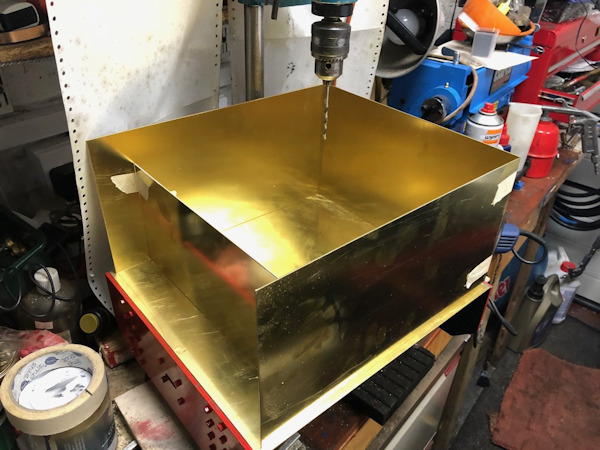

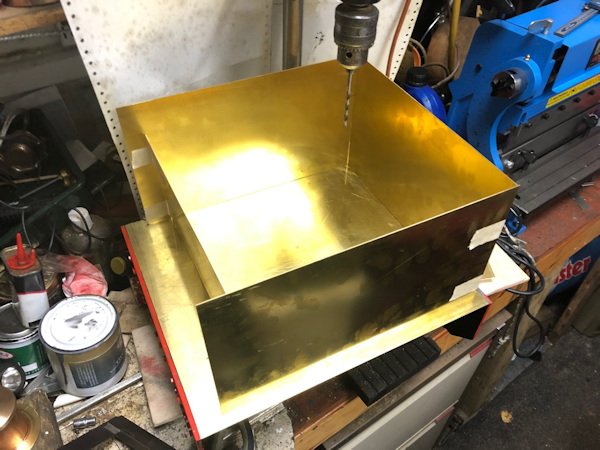

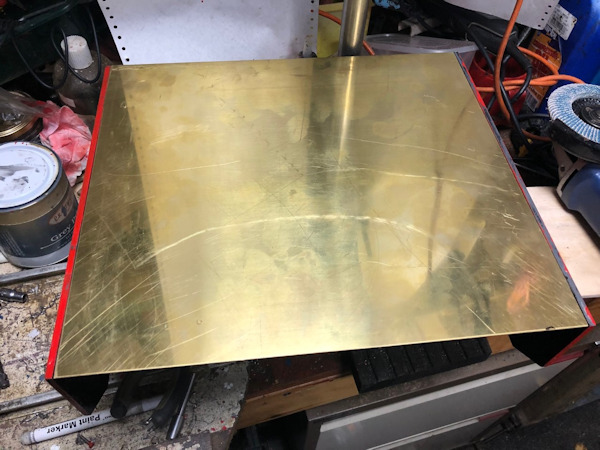

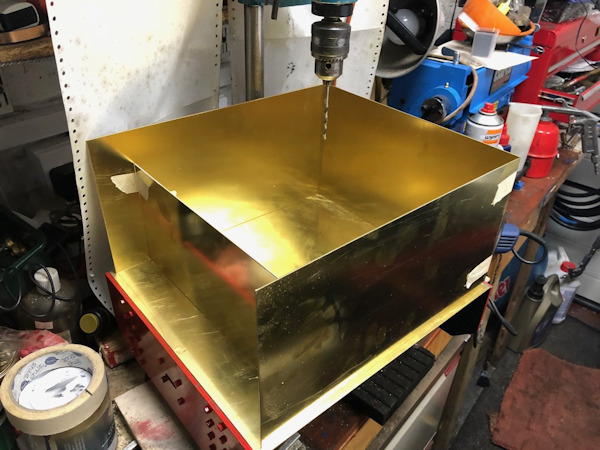

The sheet of

brass was made to fit the location by sanding a very

small amount off.

|

|

Trying for

size and what amendments to make.

The front will be placed 2" back to allow for an

injector cock to be installed and the sides will be

trimmed back by about 1"

|

|

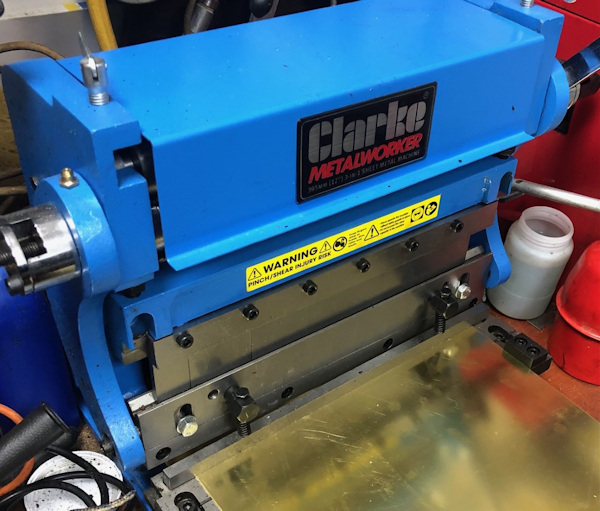

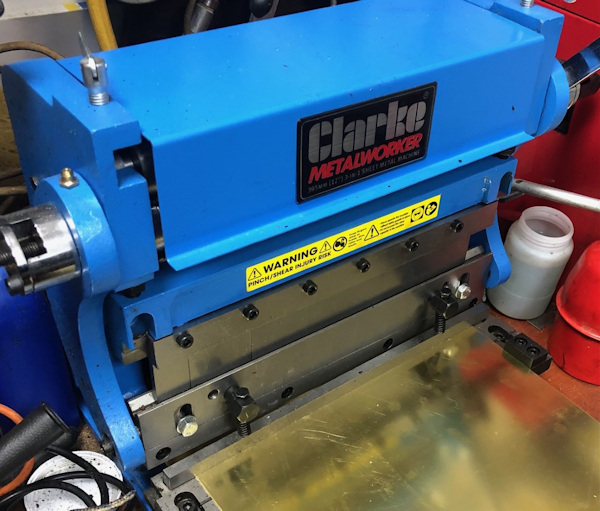

This piece of

kit made cutting the brass sheetfor where the filler

will be an easy job after careful measuring !!

|

|

The filler cap

was a simple turning exercise but cutting a small recess

in the copper pipe was a little more challenging as I

had to support the pipe at the outer end !!

The base and pipe now need to be soldered together !!

|

|

20th October

2020

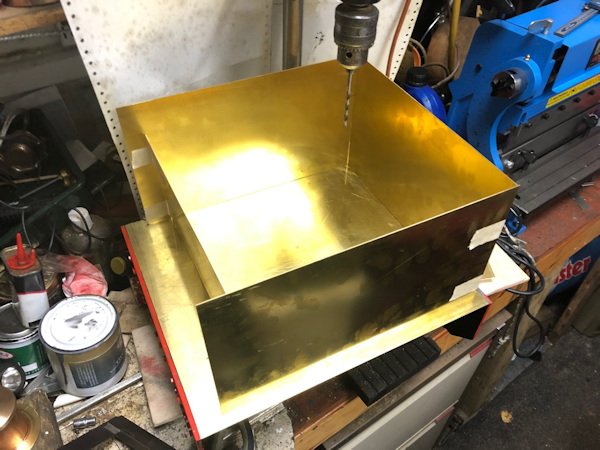

More sheets of Brass were cut to size.I wanted for the

tender |

|

|

|

|

|