The building of a Stuart S50 Engine

Crank shaft and bearings

The bearings for the crack shaft are integral to the base and more on how this was drilled and reamed can be found on another page dealing with the base.

Then the centre boss as created by reducing the outside diameter to 7/16".

It was centre drilled and then the tapping drill for 2BA selected and drilled through the bar.

This hole was then tapped 2BA using a tapping compound to provide lubrication.

The photo shows the parting of of the piece which has to be carried out with a very shap parting tool and slow hand feed to gauge the right speed to end sure a cut and no rubbing.

Coolant was applied as can be seen. The parting off to a long time to ensure no failure.

Before it was fully parted off the edges were rounded to take of the sharp edges.

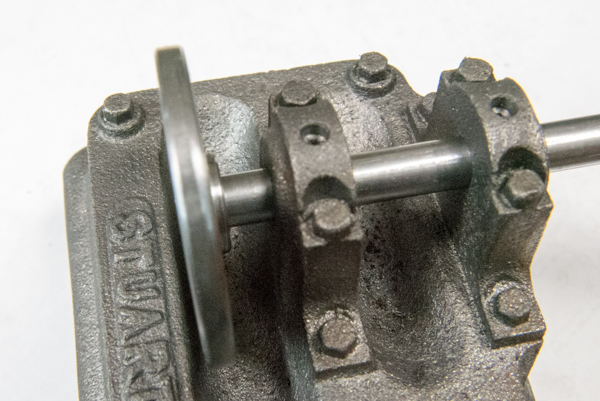

The photo shows the crack and shack installed temporally as the crack has to be profiled as per the drawings.

.

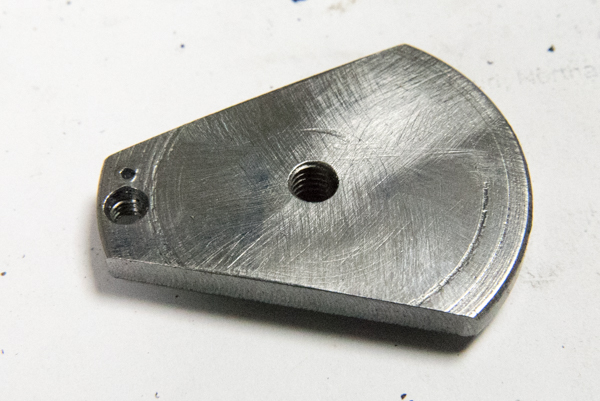

After making out the position by scribing a ling using a cutting tool in the lathe the position was centre popped but I was not satified with the position hence the reason you can see a redundant centre pop !

It was drilled and tapped for 5BA

The completed Crank