The building of a

Stuart S50 Engine

|

Eccentric

|

5th October 2018

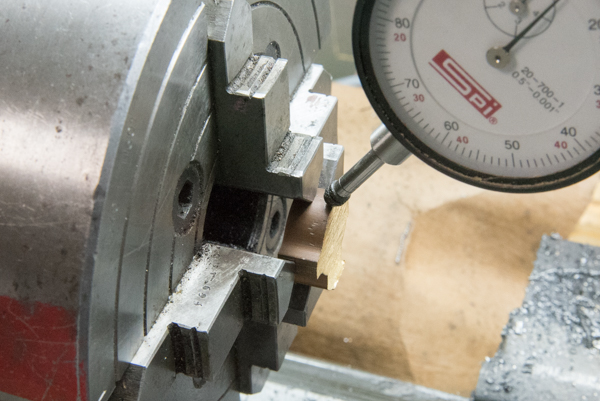

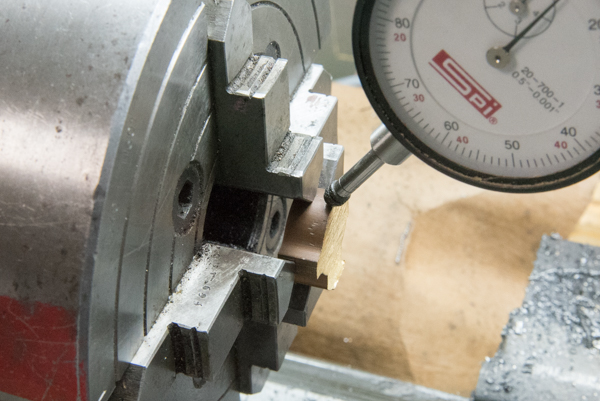

I now turn to the eccentric the cast parts for the eccentric One

side was machine flat and then the part was reversed and was

centred in a three draw chuck using a dial test indicator and

machine to thickness.

|

|

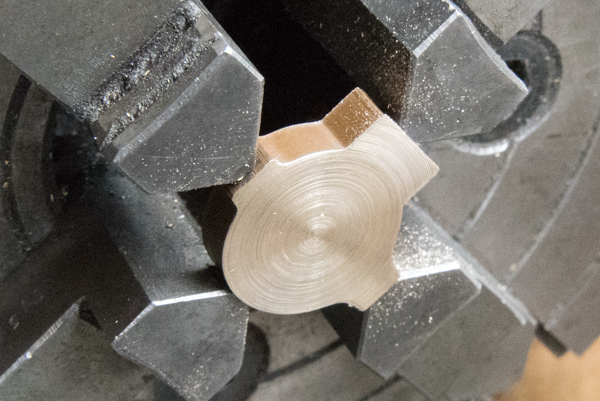

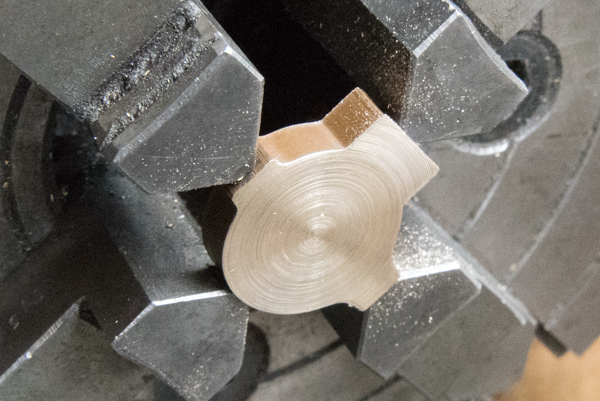

The photo show the part

brought to thickness.

|

|

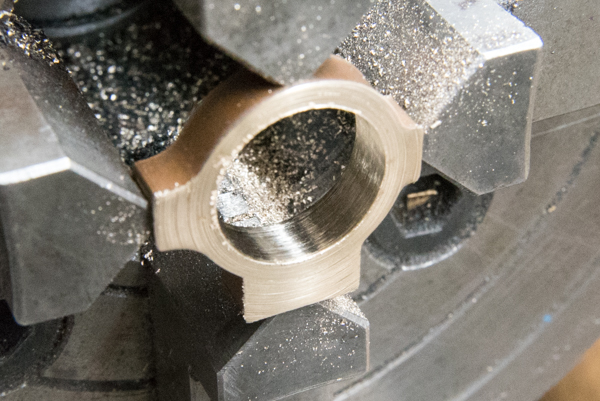

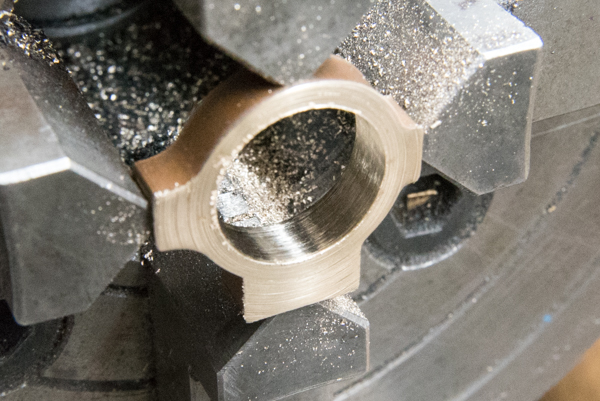

A centre was used to

make the preliminary start for a drill which followed in stages up

to 1/2” and the a boring bar completed the job

|

|

| Next eccentric centre

was machined to size and before parting off and a mark was made on

the outer and for the 3/32 inch throw The parting off was then

completed. |

|

6th October 2018

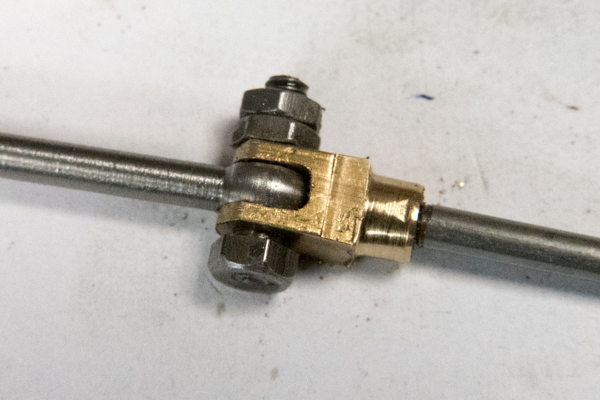

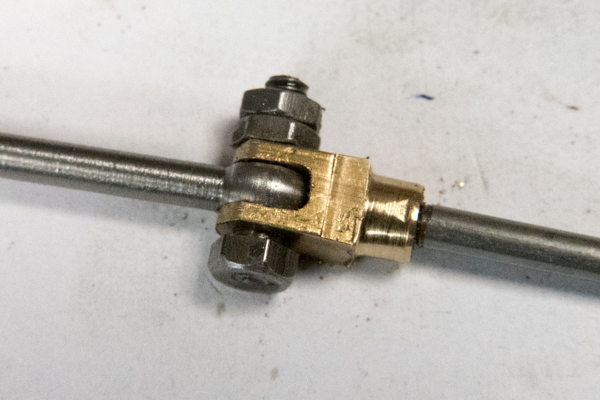

The Eccentric strap had to be drilled and tapped 7BA so that the

link can screw into it and keep in place the strap of the

eccentric.

|

|

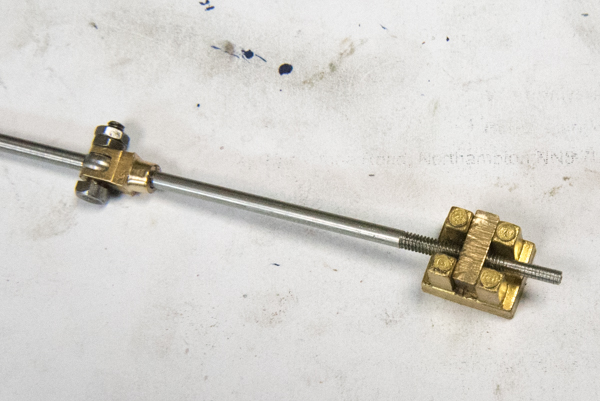

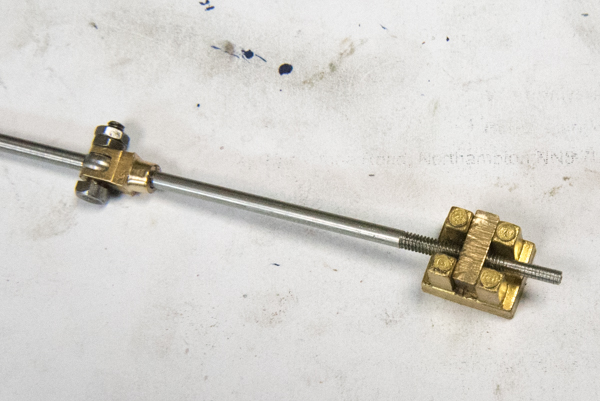

The photo shows the

Eccentric strap and eccentric kept in place by the linkage screwed

into the strap.

|

|

The linkage buckle is

the smallest parts I have ever made as it is only 1/4" wide and

3/8" long.

It took about 2 hours to make as my vice would not easily hold

such a small part.

|

|

And to the end of the

linkage which drives then slide valve.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|